15 Apr Degassing Process Aluminum Indonesia

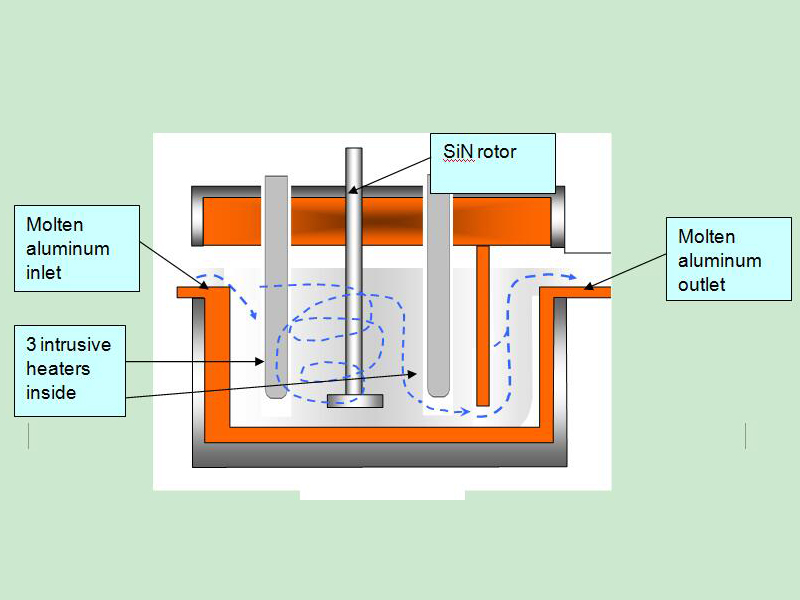

Degassing Process Aluminum Indonesia Degassing Process Aluminum Indonesia Equipment The liquid aluminum alloy purification treatment process is the main means to improve the comprehensive performance of aluminum alloy. In the purification treatment process, the purification gas and the solvent are mixed, and the method of purifying the...