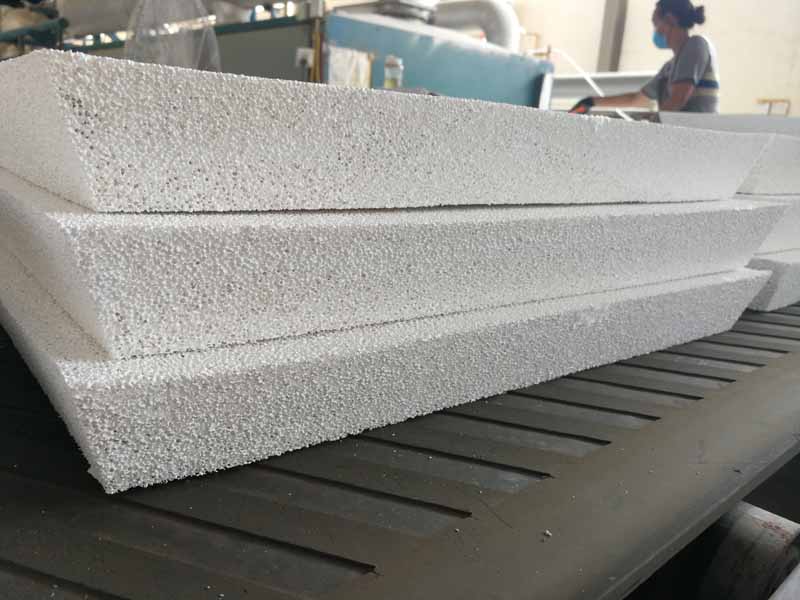

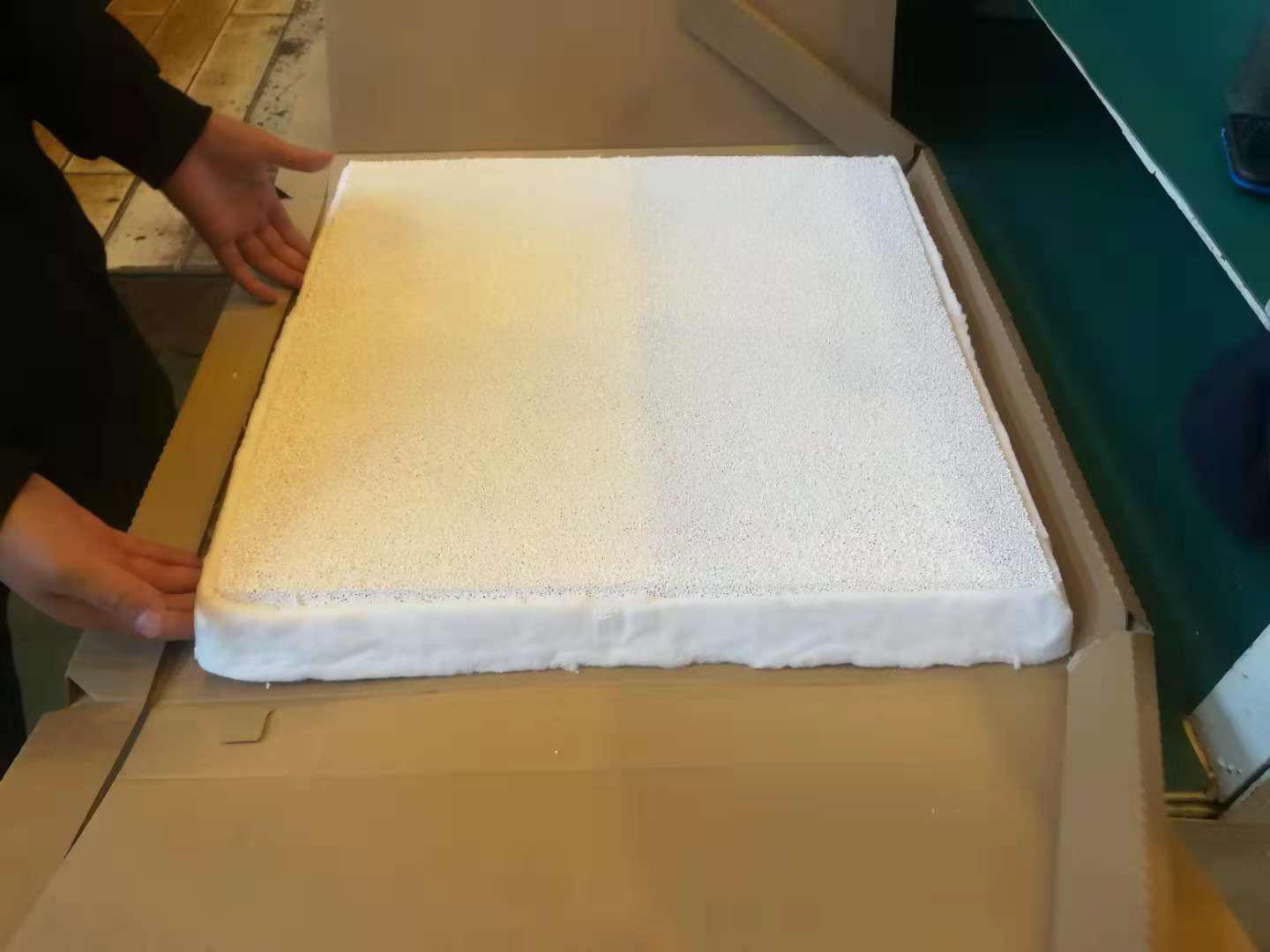

05 12月 PAL Ceramic Filter Plate

PAL Ceramic Filter Plate PAL Ceramic Filter Plate is an aluminum-water foam ceramic filter, which adopts a three-dimensional network structure and an organic bubble communicating with pores as a carrier, infiltrates the thixotropic alumina slurry, and uses a four-center correction center distance automatic extrusion process. The...