10 1月 Tundish Nozzle

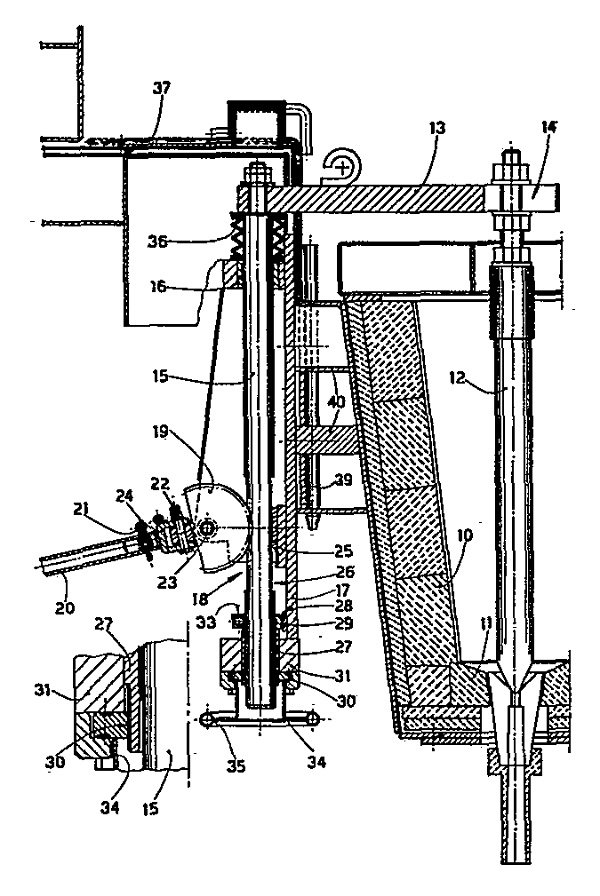

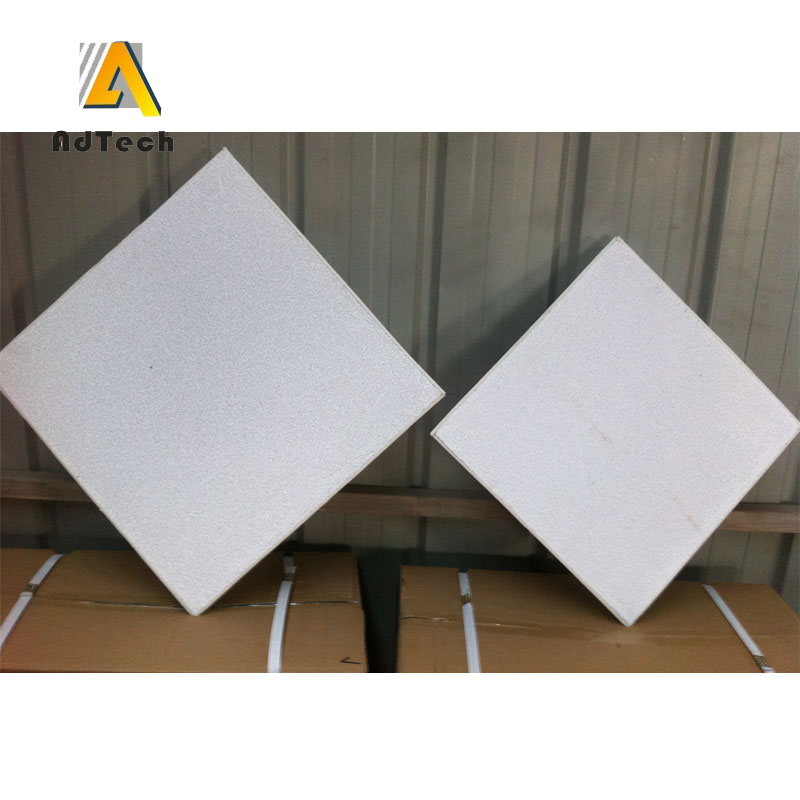

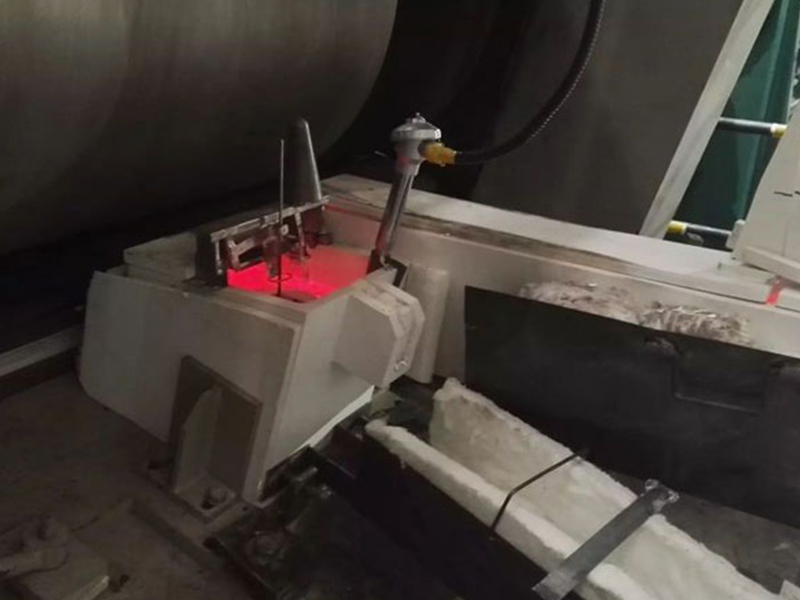

Tundish Nozzle is a complex problem that causes decreased productivity, quality defects, and increased production cost. The first step in a program aimed at the reduction of nozzle clogging is to implement a real time quantitative analysis that includes a nozzle clogging factor, rate of change...