11 May Aluminium 7075 Ceramic Filter Suppliers In India

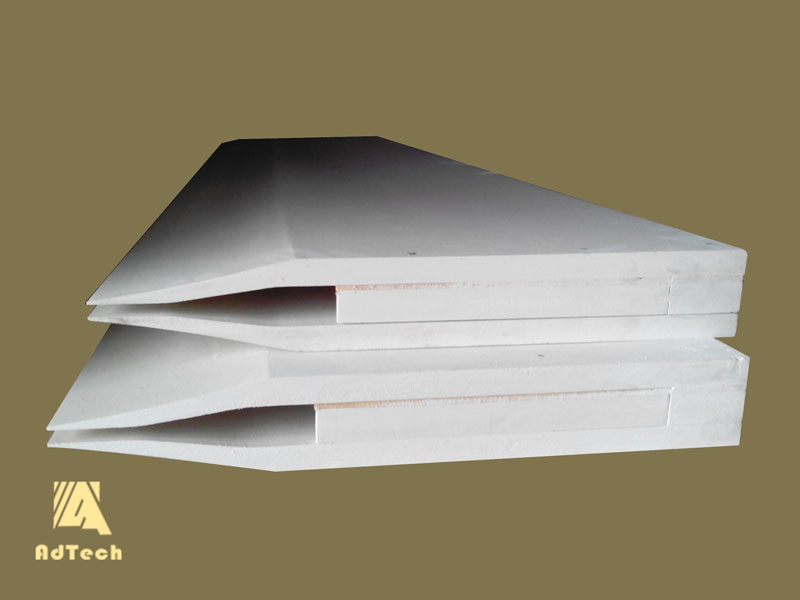

Aluminium 7075 Ceramic Filter Suppliers In India is mainly used in foundries to filter aluminum and aluminum alloy 7075. Due to its excellent corrosion resistance to molten aluminum, it can effectively remove inclusions, reduce trapped gas, and provide laminar flow. The filtered metal is significantly...