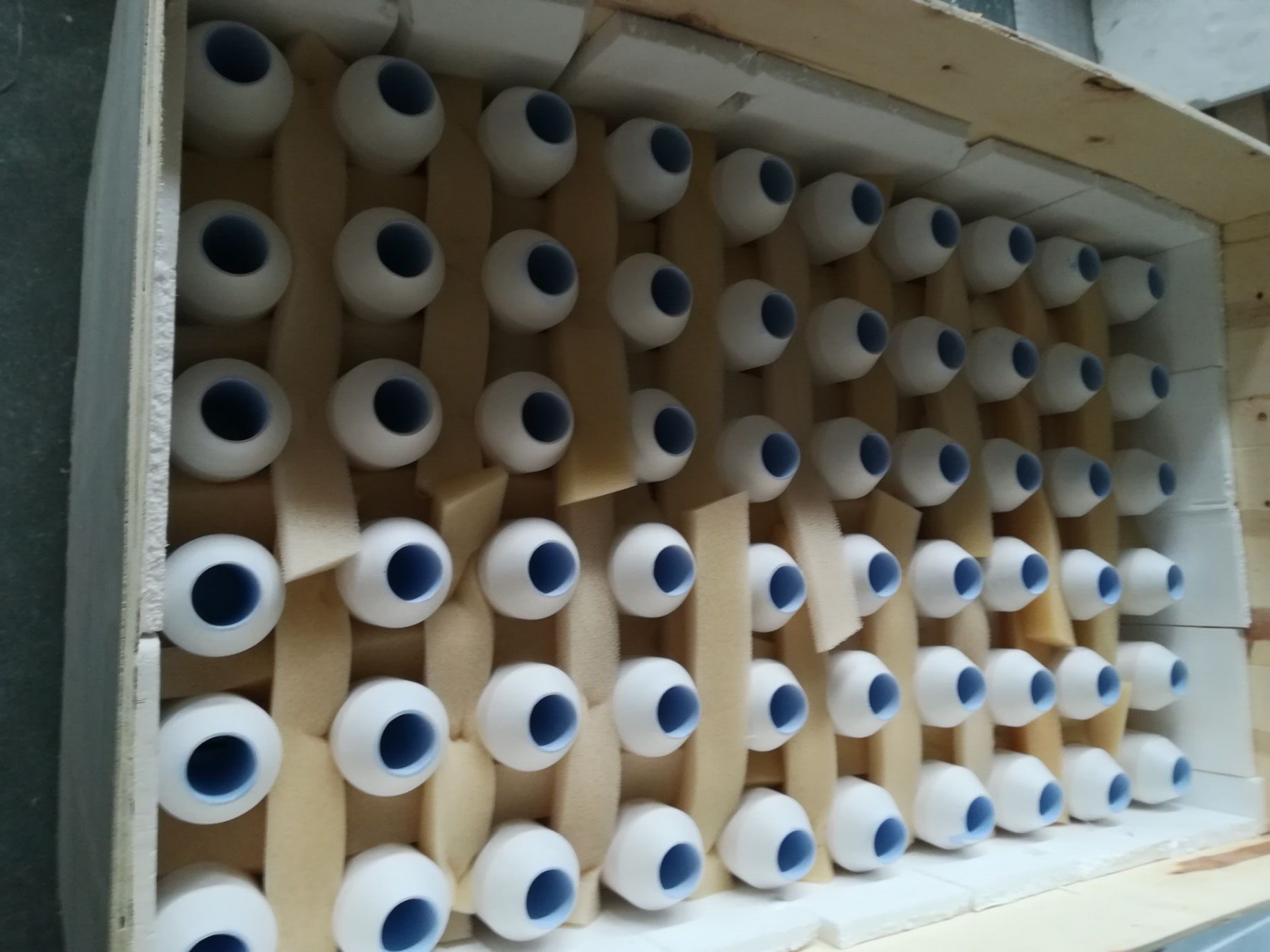

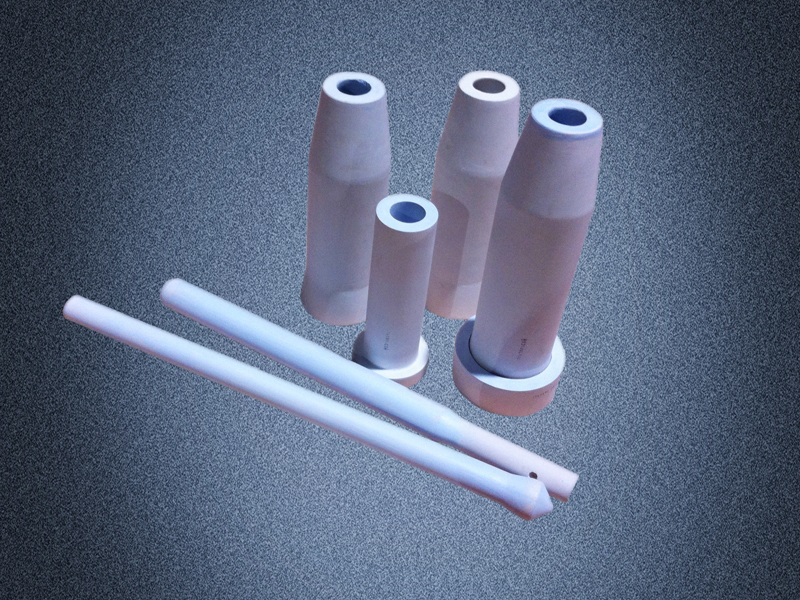

05 Mar Immersion Nozzles

Immersion Nozzles is an important part used in the aluminum and aluminum alloy casting process, mainly used in the field of aluminum liquid diversion in aluminum alloy casting. It has the advantages of moderate elasticity, small variables, and long service life. The boron nitride coating...