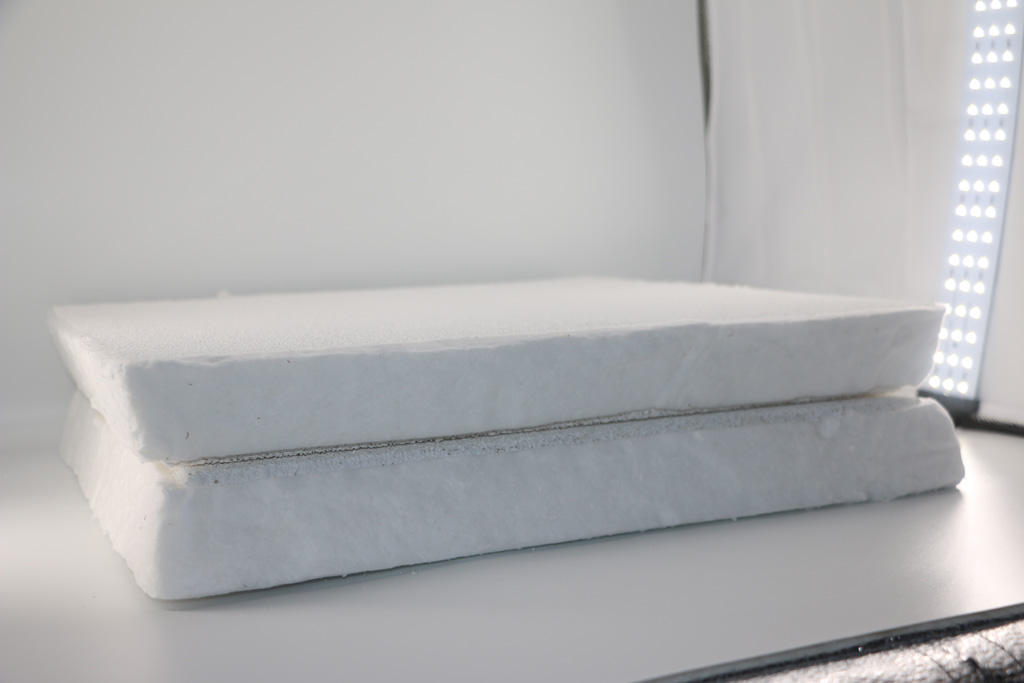

21 Feb Foam Filter Material Product

Foam Filter Material Product for aluminium casting is based on a carrier with a solid network structure and combined with organic foam cells. Production steps The carrier is put into the thixotropic alumina slurry, and the square-centered automatic extrusion process is adopted to make the slurry dry...