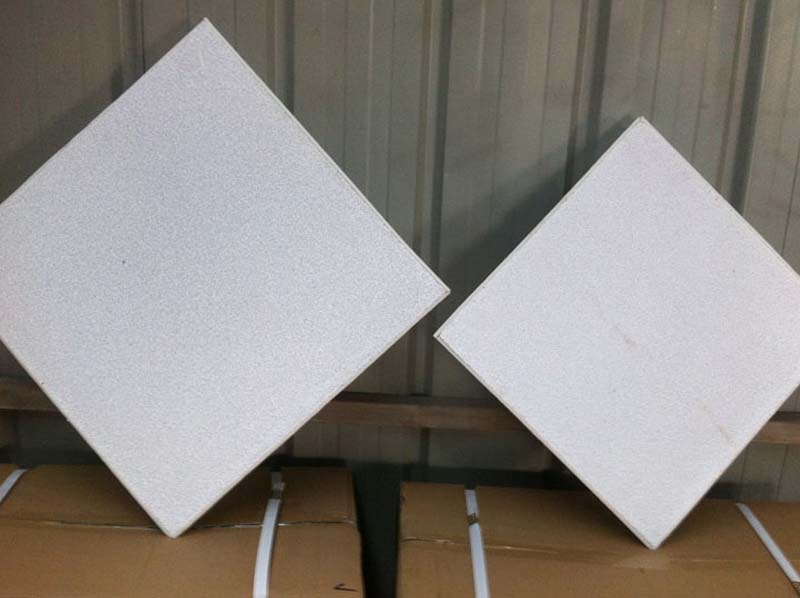

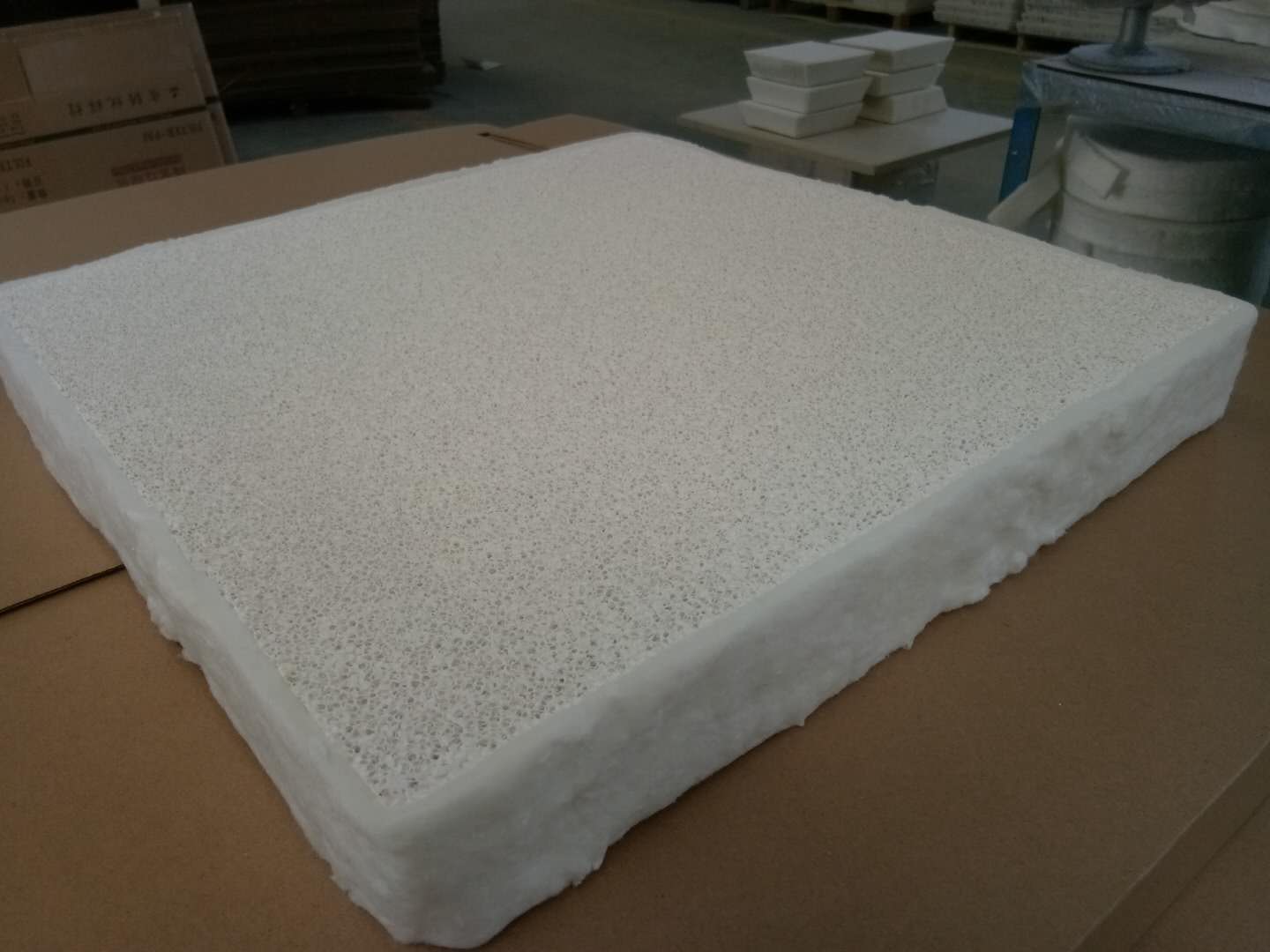

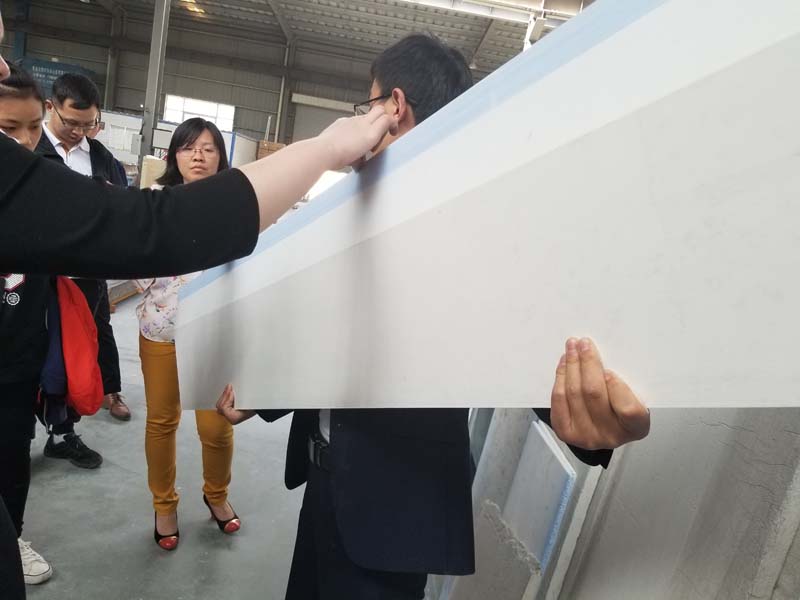

08 12月 Molten Metal Filter Media

Molten Metal Filter Media is used to filter molten aluminum. Reticulated foam filters that use alumina aggregate particles in the binder phase are usually used to filter aluminum and aluminum alloys. Generally, inclusions, especially non-metallic inclusions, are mixed into the molten aluminum. If such molten metal is...