The operation of online degassing equipment of Northwest Aluminum meets the requirements

The operation of online degassing equipment of Northwest Aluminum meets the requirements

As of June 27, 2023, the Northwest Aluminum production line has been in operation for some time, and the hydrogen content at the outlet of the degassing equipment has decreased to 0.11ml/100g-AL, which does not meet the customer’s high degassing requirements (0.1ml/100g-AL). At the request of the customer, I went on a business trip to the customer’s site to inspect the equipment operation, adjust equipment parameters, analyze the reasons for the hydrogen content not meeting the standard, and provide reasonable solutions.

From June 28, 2023, to July 20, 2023, after 23 days of tracking production on the customer’s site, it was ultimately analyzed that the reason for the hydrogen content not meeting the customer’s requirements was:

1. At present, the liquid level at the inlet and outlet of the degassing equipment is relatively low, lower than that of other manufacturers in the same industry (generally, the liquid level on the production line is ≥ half of the depth of the flow channel). Therefore, it is necessary to increase the liquid level at the inlet and outlet of the degassing equipment. This can increase the height of the liquid level inside the tank, resulting in a larger amount of aluminum liquid during operation. Argon can have a larger contact area with aluminum liquid, which can bring out more hydrogen and unleash the true degassing ability of the degassing equipment!

2. Based on our years of experience in tracking on-site equipment and hydrogen measurement, the probe of the hydrogen meter should be located in the middle of the two sidewalls of the flow channel. At the same time, the upper end of the probe should be buried 50mm (≥ 50mm) below the surface of the aluminum liquid. When the lower end of the probe is ≥ 50mm from the bottom of the flow channel, we can obtain a more realistic hydrogen content value of the aluminum liquid! This requires that the depth of the aluminum liquid at the inlet and outlet of our degassing equipment reach over 130mm!

After analyzing the cause, effective measures were taken with the customer to artificially increase the liquid level in the flow tank. The hydrogen content indicator measured by the hydrogen meter met the customer’s requirements: hydrogen content ≤ 0.1ml/100g-AL;

Typical values are as follows:y

2 series alloy: 2024 alloy

Hydrogen content at the inlet of the degassing equipment:

Hydrogen content at the outlet of the degassing equipment:

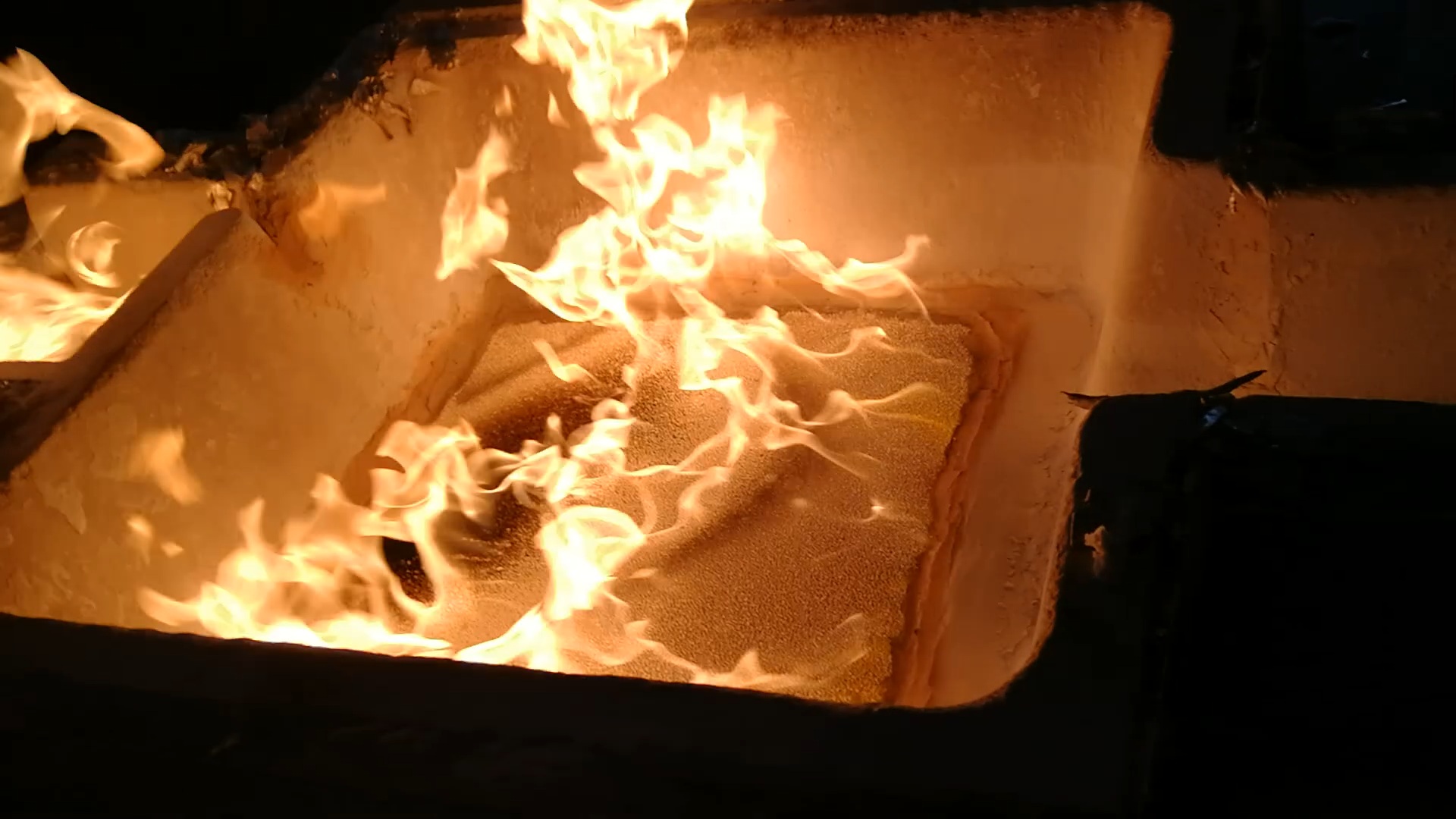

Northwest Aluminum Online Degassing Equipment

7 series alloy: 7A04 alloy

Hydrogen content at the inlet of the degassing equipment:

Hydrogen content at the outlet of the degassing equipment:

5 series alloy: 5083 alloy

Hydrogen content at the inlet of the degassing equipment:

Hydrogen content at the outlet of the degassing equipment: