22 11月 Nitrogen Degassing Unit

Nitrogen Degassing Unit

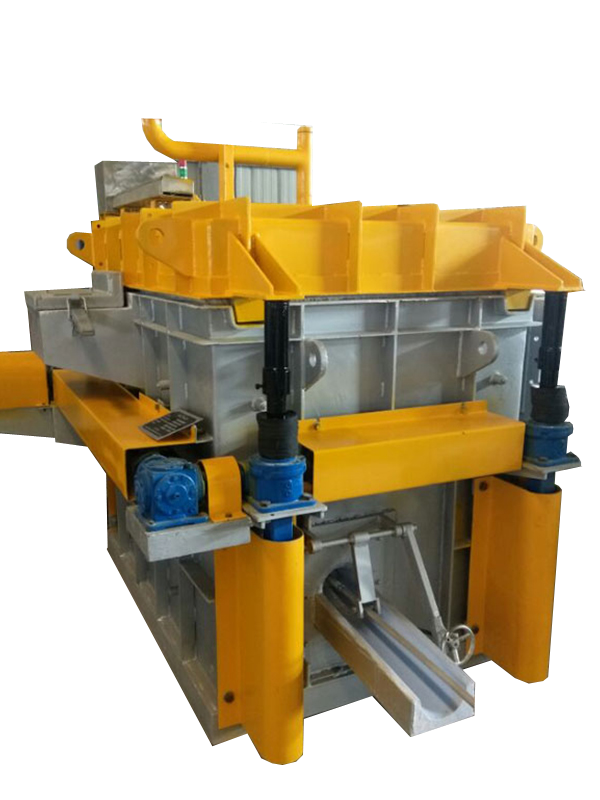

In the aluminum industry production of Nitrogen Degassing Unit and other equipment installed in the bottom of a number of diffuse permeable bricks, blowing nitrogen or argon and other inert gases.

The aluminum liquid is turned over, the impurities are floated, and the hydrogen is greatly dehydrogenated, which can greatly improve the quality of the aluminum alloy. The bottom breathable refining technology is used, and the bubbles have no dead angles, and are small and numerous.

Rolling up and down, uniform aluminum liquid temperature, aluminum alloy performance is greatly improved, and achieved good economic benefits. Nitrogen Degassing Unit has a simple structure, does not pollute the aluminum liquid, and has low use cost, long service life and simple maintenance. It is widely used in the casting of aluminum alloys in China.

During the smelting process, the aluminum metal reacts with the water vapor to generate hydrogen gas and dissolves into the aluminum liquid. When the aluminum liquid solidifies, the hydrogen gas is removed from the aluminum liquid.

If the hydrogen content in the aluminum liquid is too high, the pores are easily formed in the casting, and the mechanical properties of the casting will be degraded, which may cause the casting to be scrapped.

Hydrogen is a harmful gas in aluminum liquid. The pre-furnace detection of the hydrogen content of aluminum liquid is an important process to ensure the quality of castings. Especially in the precision die casting process, the use of Nitrogen Degassing Unit to remove hydrogen and slag will become indispensable lack.

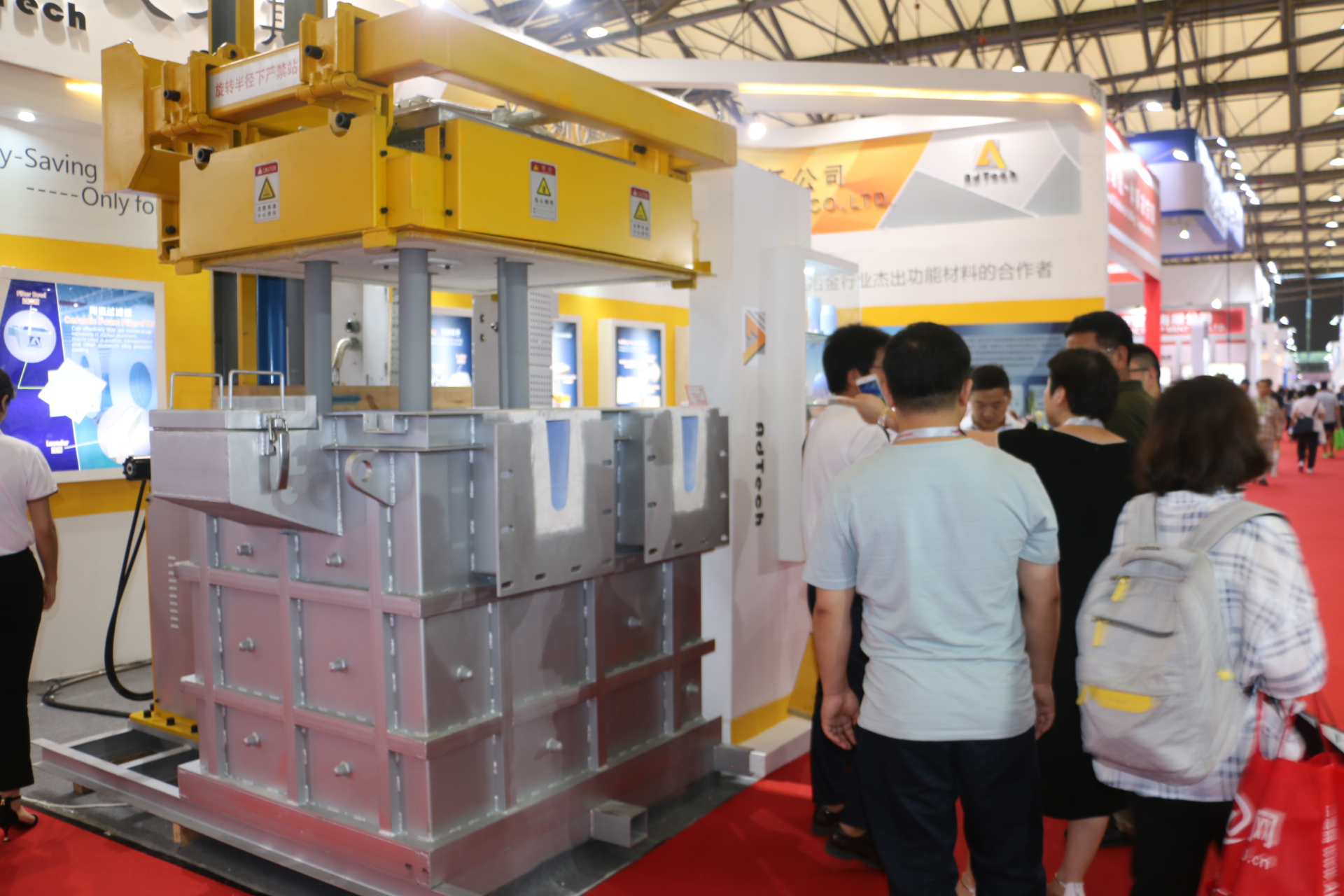

The Workplace of Nitrogen Degassing Unit

Auto parts die-casting, aluminum alloy die-casting products, lighting aluminum alloy casing, aluminum alloy spotlight shell, automotive lamp aluminum alloy shell, LED lamp aluminum alloy lamp shell, aluminum alloy die-casting heat sink, aluminum alloy die-casting tool, aluminum alloy die-casting fitting, pure Aluminum die-casting heat sinks, precision auto parts and other aluminum casting smelting processes.

The Features of Nitrogen Degassing Unit

Mobile rotary refining and degassing: easy to use, can achieve multi-purpose machine, and the operating environment is diverse.

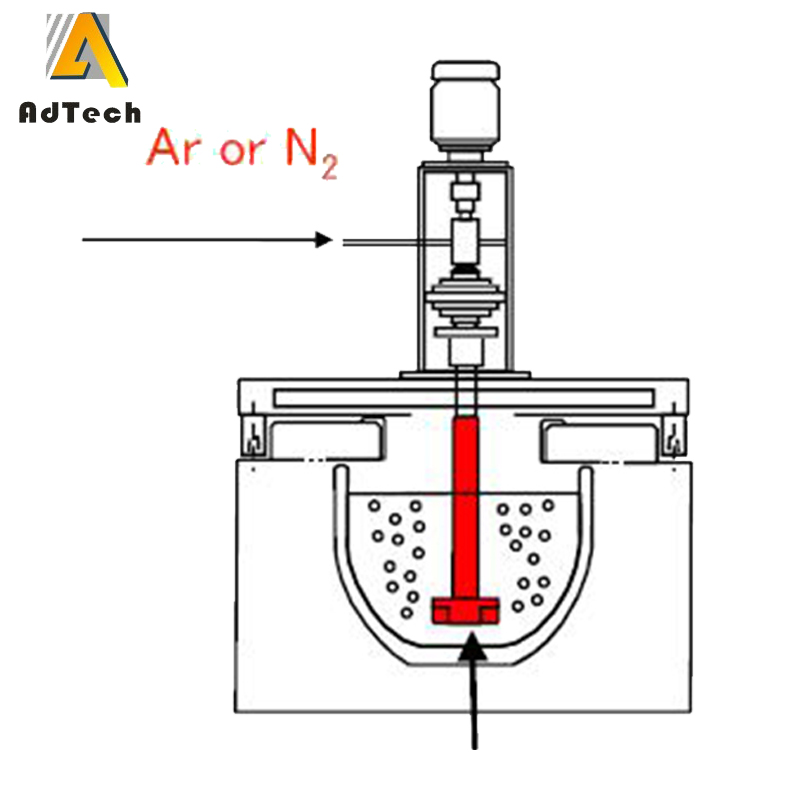

The Principle of Nitrogen Degassing Unit

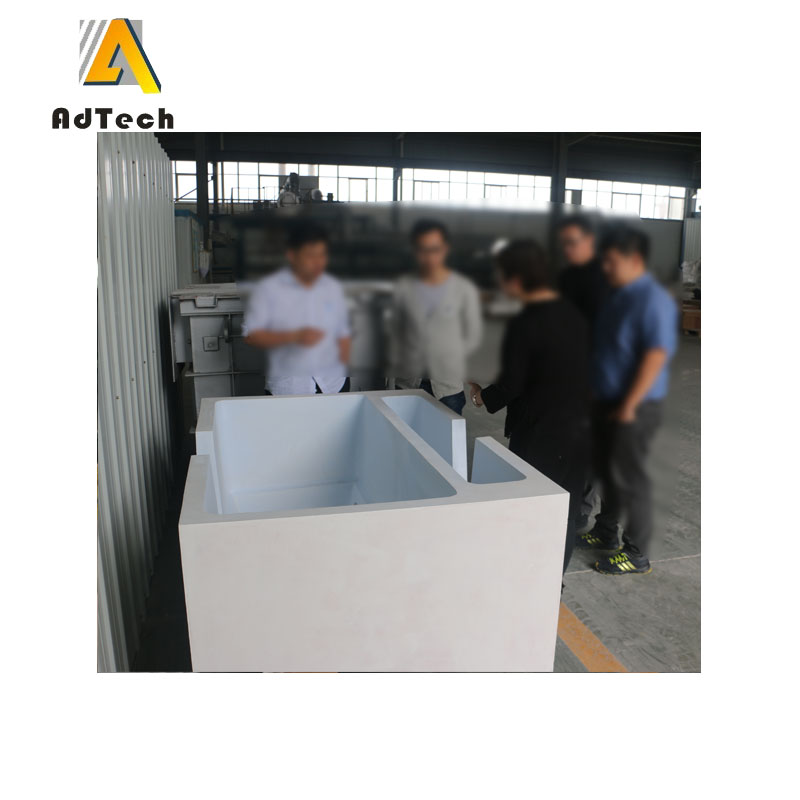

The aluminum liquid is stirred by a controlled rotating graphite shaft and a rotor, and the metered inert gas is pressed into the aluminum liquid through the rotor and dispersed into fine bubbles, which are uniformly dispersed in the liquid metal, and the gas partial pressure of the bubbles is zero.

Since the partial pressure of hydrogen in the aluminum liquid is high, the hydrogen in the aluminum liquid continuously diffuses into the bubbles, and at the same time, some non-metallic inclusions in the aluminum liquid are adsorbed on the surface of the bubble, and inertness of useless hydrogen and some non-metallic inclusions adheres. The gas bubbles float up to the surface.

When there is a special degassing filter box, these impurities are isolated before the pouring, and then the desulfurization and deoxidation inclusions are achieved by the slag. The degassing principle is also recognized, the efficiency is high, and the production is not affected. process.

It can improve the purity of aluminum liquid in a short period of time, reduce the scrap rate, improve production efficiency, improve the mechanical properties of castings, and enhance the competitiveness of products, which cannot be achieved by traditional degassing methods.

In such an application environment of aluminum liquid, graphite material and aluminum oxide material, silicon carbide material can be applied to stirring, but because the graphite rod itself has high temperature resistance, low thermal expansion coefficient (causing high temperature and low temperature conversion will not crack), moderate strength High purity, no reaction with aluminum liquid, moderate price, leading to the use of graphite rods for most manufacturers to stir. However, the use of graphite rods as degassing rotors requires attention to two points: First, graphite processing accuracy is high, especially coaxiality, otherwise it is easy to break during the rotation process.

No Comments