Ceramic Foam Filter-Alumina

About This Project

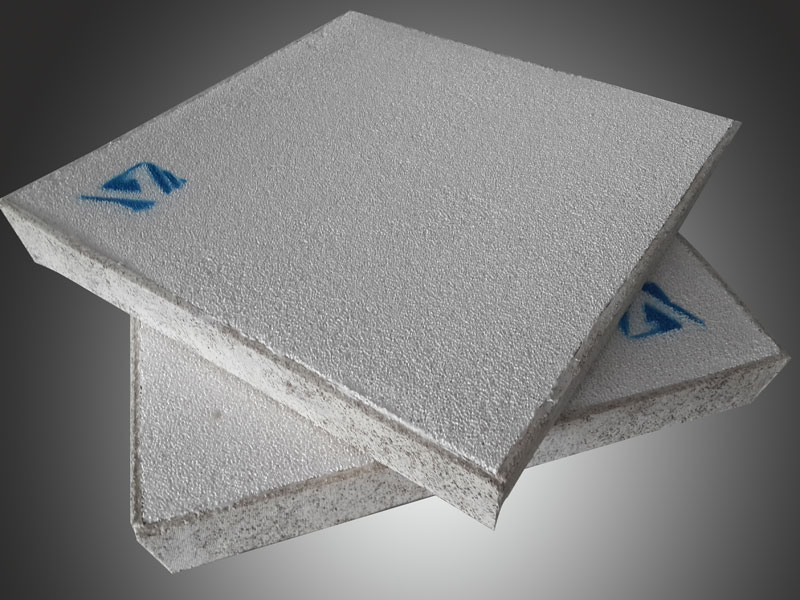

Alumina Ceramic Filter

Alumina Ceramic Filter from AdTech Metallurgical Materials Co., Ltd has been focusing on research, development, production, and marketing of the adhesive ceramic foam filter(CFF) for aluminum alloy casting. The technology of AdTech’s ceramic filter has been widely approved by the market and applied for producing multiple series of aluminum alloy products, such as PS baseboard for printing, canning materials, flexible packaging materials, railway vehicles, aerospace products, cables, electrical wires and other high-precision filtration and purification for casting aluminum alloy.

Filter -alumina

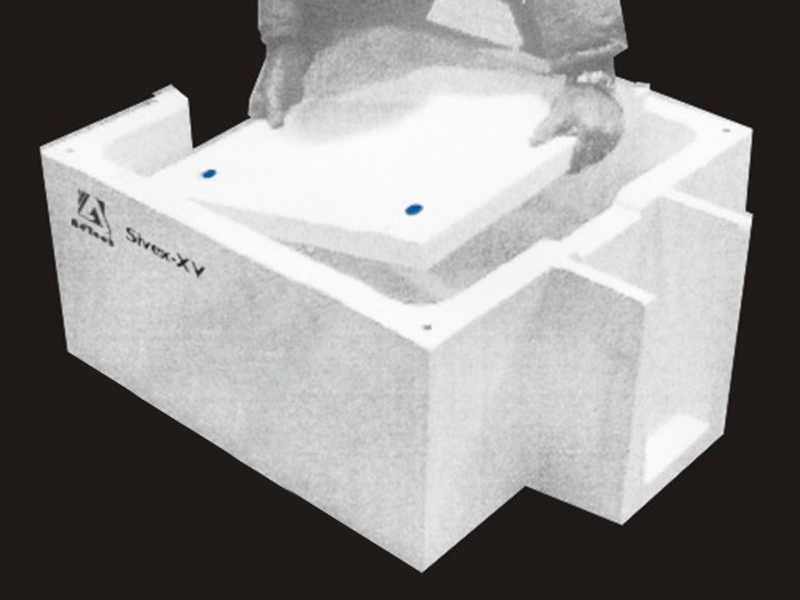

Assembles for Ceramic Foam Filter:

- Ceramic Foam Filter

- Ceramic Fiber Sealing Gasket

- Filter Bowl

Application for Ceramic Foam Filter

AdTech’s ceramic foam filter plate is produced based on the carrier with a solid reticular structure and combined organic foam pores. The production procedure is as below, put the carrier into the thixotropic alumina slurry, adopt square to center correcting automatic extrusion process, so that the slurry evenly deposits in the foam skeleton of the carrier, drying solidification, the carrier will turn into the final product by roasting formed under 1180 ℃ high temperature. A filter is installed in the filter bowl for filtrating impurities in molten aluminum alloy, which helps to meet the requirement of production in high value-added, high-tech performance aluminum alloy precision casting, such as computer hard drive, PS baseboard for printing, canning materials, fan blades for turbojet engine, etc.

Advantages of Ceramic Foam Filter

- Adopt the adsorption principle for the filter, which can effectively remove big piece inclusions in molten aluminum, and effectively adsorb tiny inclusions.

- No broken bits drop out, effectively reducing the pollution of molten aluminum.

- Superior thermal shock resistance improves erosion resistance ability of molten metal.

- Automatic flow production, 3 calibration procedures, precision size, fit the filter bowl tightly.

- Improve the surface appearance and performance, and purify molten aluminum.

Filtration Rate of Ceramic Foam Filter

The filtration Rate of our Ceramic Foam Filter is based on the filter’s pore size, inclusion size, type (density, wetness performance), and flow speed of molten metal through the filter.

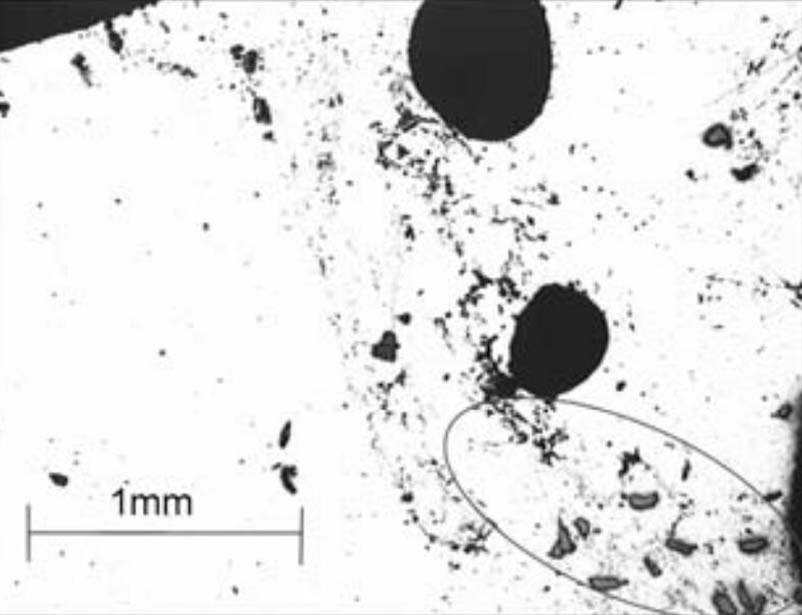

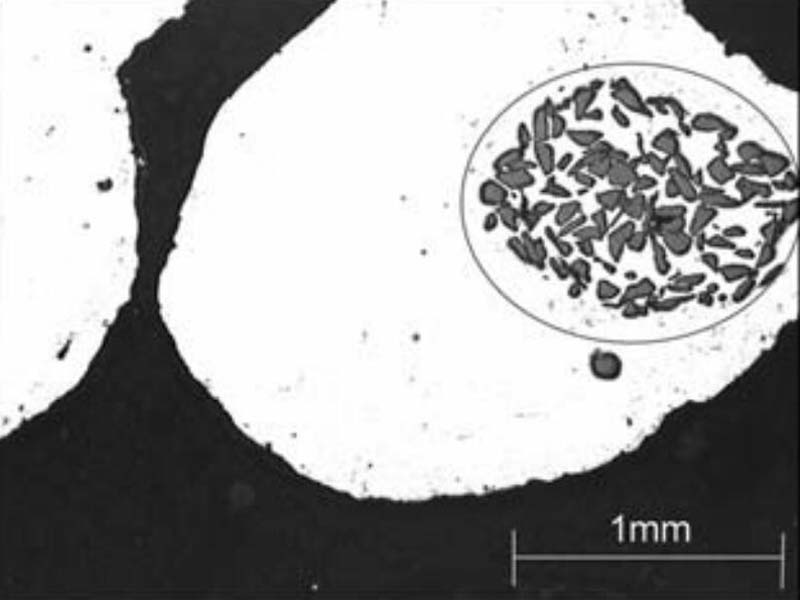

Graphic (Alu alloy 5082):

Under the microscope can see the magnesia group sticky on the Alumina filter plate.

Graphic for adsorption micrometer inclusions.

Sealing gasket for Ceramic Foam Filter

The ceramic filter is surrounded by a Sealing gasket, laying between the filter and filter bowl, to prevent molten aluminum from leaking through an interface. AdTech’s filter adopts sealing gasket in 3 different types, fiber paper material, fiber cotton material, and expanding cotton material.

Photos for 3 different material Sealing gasket

Standard sizes for Ceramic Foam Filter

Dimension (± 3 mm

): 7x7in 9x9in 12x12in 15x15in 17x17in 20x20in 23x23in 26x26in

Thickness: 50 ± 2 mm

Bevel Angle: 17.5± 1.5°

Special Dimension: square, rectangular, round, trapezoidal, abnormal, or customized as per the requirement.

Technical Parameters:

| Item | Density

(g/cm³) |

Rupture Modulus

(816℃ /Mpa) |

Comprehensive Strength

(Mpa) |

Operating Temperature(℃) | Sealing gasket expanding temperature (℃) |

|---|---|---|---|---|---|

| Index | 0.45 | 5. 5 | 0. 8-1.0 | 1550 | 450-550 |

Pore size for Ceramic Foam Filter:

Pores amount in any 25.4mm length filter

| Mesh Number(PPI) | 10 | 20 | 30 | 40 | 50 | 60 |

|---|---|---|---|---|---|---|

| Pore Density(PCS) | 8-12 | 18-22 | 28-32 | 38-42 | 48-52 | 58-62 |

| Pore Mesh Number Range | Alumina Filter Pore Size Specification | ||||

|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | |

| Minimum Pore Size(um) | 1,875 | 1,066 | 815 | 624 | 477 |

| Maximum Window Size(um) | 1,578 | 1,320 | 1,010 | 773 | 591 |

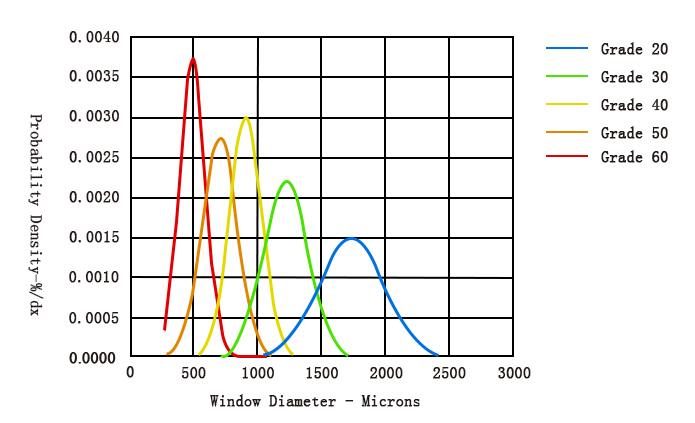

Distribution curve of pore size for Ceramic Foam Filter:

Filtration Precision for Alumina Ceramic Filter

| Pore Size(PPI) | 20 | 30 | 40 | 50 | 60 |

|---|---|---|---|---|---|

| Inclusions Diameter(um) | 80 | 40 | 20 | 10 | 5 |

| Filtration Rate(%) | 78 | 85 | 88 | 92 | 95 |

Application Data for Alumina Ceramic Filter

| Specifications (mm) | Effective filtration area(%) | Filtration flow range(kg/min) |

|---|---|---|

| 7in(178*178*50) | 75 | 22-56 |

| 9in(229*229*50) | 75 | 25-80 |

| 12in(305*305*50) | 80 | 50-156 |

| 15in(381*381*50) | 85 | 85-252 |

| 17in(432*432*50) | 86 | 110-335 |

| 20in(508*508*50) | 88 | 160-478 |

| 23in(584*584*50) | 89 | 210-640 |

| 26in(660*660*50) | 90 | 276-830 |

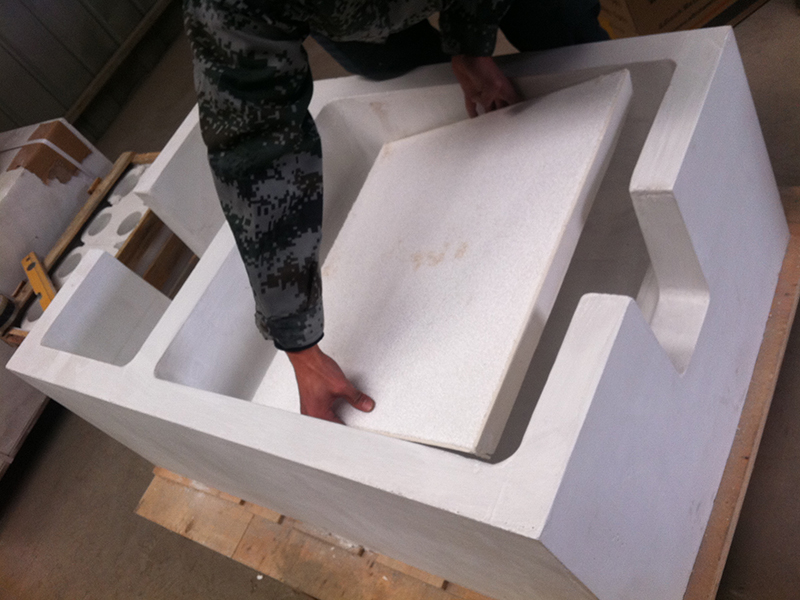

Packing Specification for Ceramic Foam Filter

Standard pallet, quantified packaging, and approximate weight

| Standard Pallet, Quantitative Packaging, and Weight | |||||

| Filter Dimensions (mm) |

Filter QTY per Case (Pcs) |

Case QTY per Pallet (Case) |

QTY per Pallet (Pcs) |

Pallet Dimension (mm) |

Pallet General Weight (Kg) |

|---|---|---|---|---|---|

| 660x660x50(26″) | 4 | 8 | 48 | 1100*1100*2200 | 490 |

| 584x584x50(23″) | 5 | 12 | 60 | 950*950*2050 | 510 |

| 508x508x50(20″) | 5 | 18 | 90 | 1100*900*1720 | 470 |

| 432x432x50(17″) | 5 | 24 | 120 | 1100*1100*1670 | 450 |

| 381x381x50(15″) | 5 | 24 | 120 | 1100*1100*1540 | 430 |

| 305x305x50(12″) | 10 | 16 | 160 | 1000*1000*1550 | 350 |

| 228x228x50(9″) | 10 | 20 | 200 | 1100*1100*1400 | 310 |

| 178x178x50(7″) | 10 | 20 | 200 | 1100*1100*1400 | 220 |

Instructions for Alumina Ceramic Filter

- Inspect and clean the surface of the filter bowl, and keep it clean and intact.

- Gently lay the filter in the filter bowl, and press the sealing gasket around the filter by hand to prevent molten aluminum from dispersing or floating away.

- Use electric or gas burning to preheat the filter bowl and ceramic foam filter evenly for 15-30 minutes, making sure their temperature is close to molten aluminum. The preheating temperature for the ceramic foam filter should be above 260℃. Expanding cotton will seal after preheating. This procedure makes the ceramic foam filter steadily fixed in molten aluminum. Preheating also leads ceramic foam filter pores to open and avoid occlusion caused by thermal expansion and contraction.

- Observe the change of molten aluminum height, and hold molten aluminum flow in standard needs. Normal starting molten aluminum height is 100-150mm. The height falls below 75-100mm when molten aluminum flows, and it will slowly increase later.

- Do not hit or shake the ceramic foam filter infiltration. At the same time, control the molten aluminum flow rate in the launder system, never to be too much or too little.

- Take out the ceramic foam filter and clean the filter bowl in time after filtering.

Storage for Alumina Ceramic Filter

Stored in a ventilated and dry environment, moisture-proof, do not lay anything on.