Plate-Type Filtering Unit

About This Project

AdTech, established in 2012, is a manufacturer specializing in the production of aluminum and aluminum alloy online degassing and filter boxes. Adtech has gained positive feedback and a good reputation in domestic and foreign markets.

Online plate-type filtering unit adopts advanced high silicon melting technology. Mainly used for the molten aluminum purification with high value-added and high technical performance. To replace the high cost ceramic tubular filtering unit and ordinary plate-type filtering unit. The micron level impurities in molten aluminum can be removed by this unit with our related technical guidance. Such as the casting for aluminum alloy in rail transit, micron foil, PS plate in printing industry.

Filter-AOE

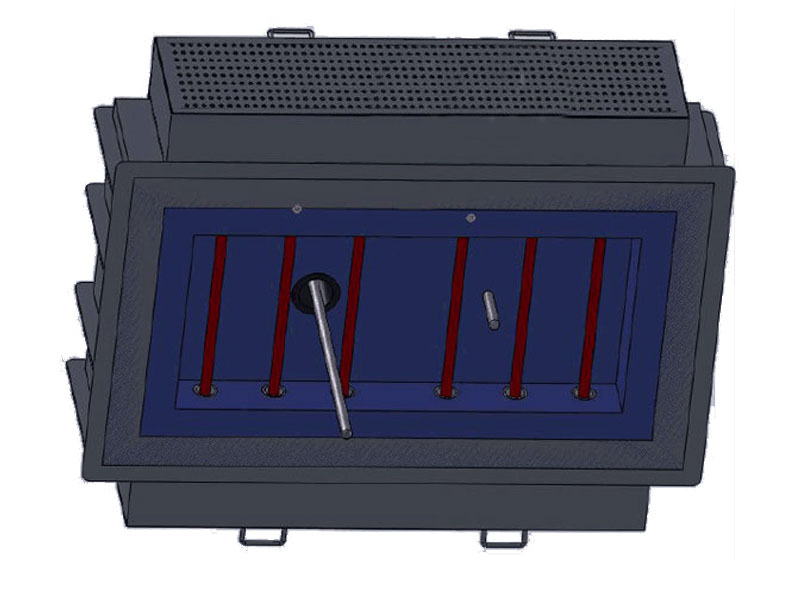

Assembles

- Mechanical Device

- Tank Body and Cover

- Heater

- Electric Controller

Plate-type filtering unit application:

It is used for the filtering and purifying of the molten aluminum, matching with the ceramic foam filter. It can filter the inclusions and tiny particles in the molten aluminum. Especially suit for the casting high purity aluminum and high precision aluminum alloy. It has the advantages with thermal resistance, anti-oxidation, corrosion resistance, warming up quickly, long lifetime and acid resistance.

Advantages:

- It is made of the high purity silicon carbide material. The normal service temperature is 1450℃, it can be used continuously for 2200 hours. Features thermal resistance, anti-oxidation, corrosion resistance, warming up quickly, long life time and acid resistance.

- The casing is welded by the steel plate and adopted to the advanced rust removal process and corrosion-resistance coating.

- With lifting and rotating device, small size, high accuracy, complete synchronization, good self-locking performance, stable structure.

- The lining is made of high silicon melting material. Non-stick aluminum, high corrosion resistance, can prolong the life time.

- With reasonable design and high absorbed ceramic foam filter.

Parameters:

|

Specification |

Filtering mode |

lifting method |

The lining |

Heating cover |

|---|---|---|---|---|

|

15in |

Hydraulic rotation/ mechanical rotation/ flip open |

Can be produced separately |

||

|

17in |

Primary filtration / two-stage filtration |

Hydraulic rotation/ mechanical rotation/ flip open |

Can be produced separately |

Can be produced separately |

|

20in |

Primary filtration / two stage filtration |

Hydraulic rotation/ mechanical rotation/ flip open |

Can be produced separately |

Can be produced separately |

|

23in |

Primary filtration/two stage filtration |

Hydraulic rotation/ mechanical rotation/ flip open |

Can be produced separately |

Can be produced separately |

|

26in |

Primary filtration/two stage filtration |

Hydraulic rotation/ mechanical rotation/ flip open |

Can be produced separately |

Can be produced separately |

Photos for lifting method:

Flip open type

Flip open type

Hydraulic rotation type

Heating cover

Mechanical rotation type

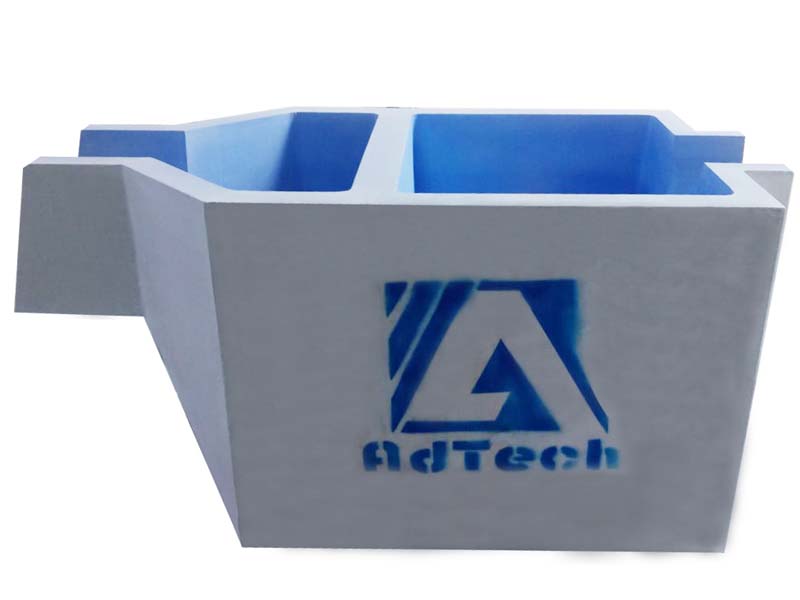

The lining of the plate-type filtering unit:

The lining is made of high silicon melting material. Non-stick aluminum, high corrosion resistance, can prolong the life time.

Non-sticking test for lining material:

Filter box lining

Test of non-sticking

Packaging of the plate-type filtering unit:

Instruction:

- Install filter box in steel casing according to the drawing.

- Put insulation board at the bottom and sides of steel casing and then install the filter box properly.

- Keep the filter box lining clean, no damage and no gap.

- Preheating the installed filter box properly, use electric heating or gas flame heating , avoid direct fire contact box wall. Maximum temperature is within 850℃ to remove the adsorption of crystal water. Make sure safety and efficiency.

Warranty:

Life time of fiber box lining: more than two years

Life time of equipment: more than three years (except for the wearing parts)