Molten Aluminium Casting Flux

Category

Flux seriesAbout This Project

Molten Aluminium Casting Flux is composed of various non-sodium salts and other inorganic compounds in specific proportions. Mainly used for the refining of molten aluminum alloys such as aluminum rods, aluminum ingots, and automobile and motorcycle wheels.

The main advantages of Molten Aluminium Casting Flux

1. It reacts in the melt, releasing various gases, refining and removing the slag in the molten aluminum.

2. It does not contain sodium, which can avoid or reduce the appearance of white spots on the surface of aluminum and aluminum alloys, and improve the surface quality of the product.

3. Using this refining agent can also greatly improve the crushing effect of the phosphorus modifier.

How to use sodium-free refining agent

Within the refining temperature range, put a certain amount of flux into the bell jar, press into the molten aluminum, and move smoothly to different parts until the flux is completely reacted. If it is a large reflective furnace, the product can also be sprayed into the molten aluminum with a powder spray gun. Inside, it’s better to mix well.

Or sprinkle this product evenly on the surface of the molten aluminum to fully mix the aluminum slag, and the molten slag will dry and become powdery, separate well from the molten aluminum, and be loose and easy to remove.

In many industrial manufacturing processes in China, especially in the aluminum smelting process, various refining agents are added to improve product performance.

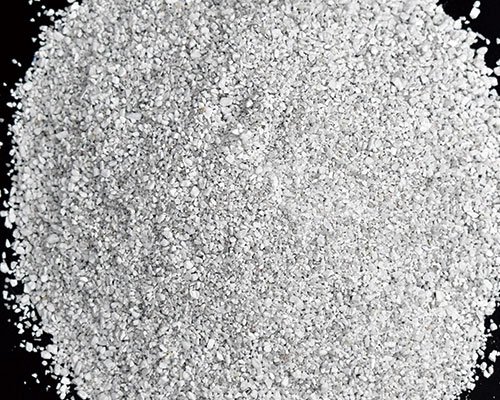

Refining agent is one of the common solvent products, mainly white powder or granules, treated with a variety of inorganic salts, with a specific ratio.

The role of Casting Flux and how to use it

Adding an appropriate amount of refining agent when smelting aluminum products can effectively remove the hydrogen and floating oxide slag contained in the aluminum liquid.

The main reason is that the refining agent is easy to decompose at high temperature, especially the generated gas is prone to chemical reaction. The high adsorption capacity of slag can make hydrogen escape from the melt, so it can ensure the slag removal. Effect.

It is a good choice for enterprises that have high requirements for pure aluminum smelting, and has won unanimous praise and recognition from customers and friends.

In fact, molten aluminum refining agent is relatively easy to use, you can learn more about its use before use.

Sprinkle it evenly on the surface of the liquid, quickly press it into the aluminum liquid, stir it evenly, and let it stand for slag removal.

During use, you can use a spray bottle. It is best to use an inert gas to atomize it. The dosage is about 0.3% of the weight of molten aluminum. If the purity of molten aluminum is relatively high, please add more refining agent.

When melting aluminum alloy, adding an appropriate amount of refining agent can play the role of degassing and removing impurities, making the aluminum alloy solution cleaner and improving its mechanical properties. Many precautions need to be taken when