Phosphorus-free ceramic foam filter successfully trial-produced

Category

Filter&purification series, Phosphorus-free ceramic foam filterAbout This Project

At present, the ceramic filter plates used for filtering and purifying solid inclusions in the aluminum melt are mainly phosphate-bonded alumina ceramic foam filters, which have the characteristics of good filtration and purification effect and low cost of use, but they are used for the filtration of high-magnesium aluminum alloys. During purification, the binder AlPO4 will react with magnesium: Mg+AlPO4→Mg2P3+MgO+AlP, resulting in damage to the structure of the filter plate, and in severe cases, particles will fall off and pollute the aluminum liquid.

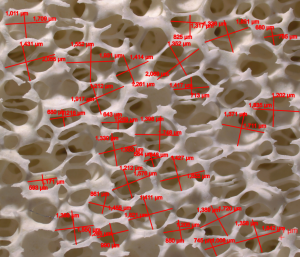

Phosphorus-free ceramic foam filter adopts non-phosphate boron binder, and the product has the characteristics of no pollution in the production process, corrosion resistance in the use process, and no pollution after use; the product has low thermal expansion coefficient, lightweight, high porosity, and the channels have micropores and The convex structure, good adsorption of fine inclusions, and high filtration and purification efficiency is mainly used in the filtration and purification of high-end products and high-magnesium aluminum alloys.

Phosphorus-free ceramic foam filters can only be produced by a company in the United States. The domestic market is completely dependent on imports from the United States. The cost of use is relatively high, and it may become a “stuck neck” product at any time; Tackling key problems and continuously overcoming difficulties, successfully developed a phosphorus-free ceramic foam filter suitable for high-magnesium aluminum alloy filtration and purification, laboratory research has made breakthrough progress, completed small batch preparation of trial samples, and the product’s compressive strength is ≥ 1.0MPa, Porosity ≥ 85%, excellent thermal shock performance, uniform pore size distribution.

Phosphate-free ceramic foam filter