24 6月 Reticulated Cff

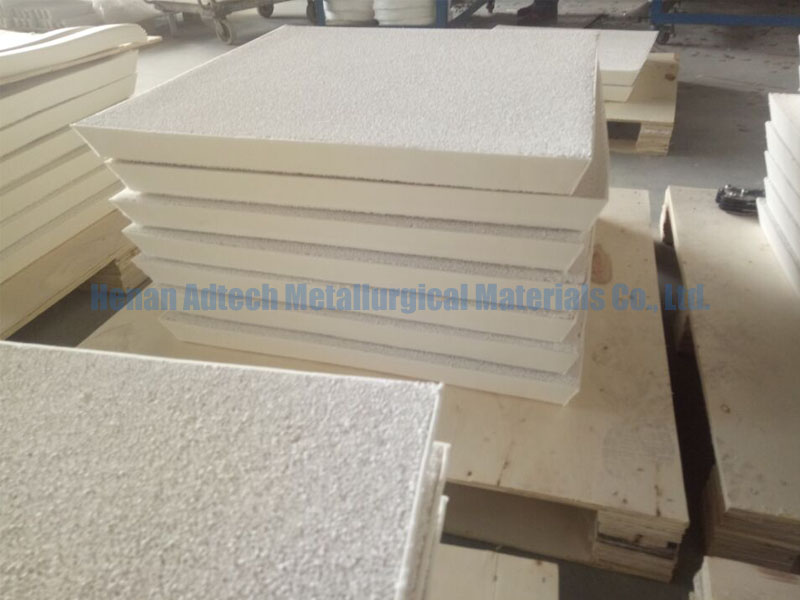

Reticulated Cff is suitable for the production of high-quality and high-required aluminum profiles. Through physical adsorption and chemical action, it can effectively filter various oxidation inclusions generated in the aluminum smelting process, thereby reducing casting defects and improving casting quality. Deep processing provides high-quality materials.

There are many ceramic materials for Reticulated Cff, such as alumina ceramics, silicon carbide ceramics, zirconia ceramics, etc. The effects achieved by different materials are not the same.

In general, alumina ceramic filter plates can be used to remove impurities, impurities, fine particles, etc. in the aluminum liquid. It is often used when improving the quality of the aluminum liquid. The improvement of the quality of the aluminum liquid can improve the yield and improve the product quality. Therefore, it is often used in the aluminum industry.

The so-called light transmittance refers to the data obtained by placing the ceramic filter plate on the transparent plate of the incandescent lamp box and calculating the ratio by looking at the size of the light transmission area outside the filter plate.

The higher the light transmittance, it proves that the filter holes of the ceramic filter plate are unobstructed, and the better the filtering effect is.

Reticulated Cff fine particle composition

Discuss from two stages of sintering (the evaporation period and the vitrification period).

Discuss from two stages of sintering (the evaporation period and the vitrification period).

During the evaporation period, the free water of the porcelain slurry and the water on the surface of the material have been basically removed during the drying and drying process. Evaporation period refers to the removal of crystalline water of foam plastics and materials.

After sintering, it will reduce the strength of the Ceramic foam filter, and even become a waste product. A large amount of crystallization water escapes from the material, and the low melting point material and the components of the user 3 dissolve and diffuse with each other.

1. The main technical index of the developed foam ceramic filter plate is 2.47MPa, which is superior to the purchased products. The ceramic filter plate has smooth appearance, regular shape, no cracks, dross and other defects. Moreover, the pores are uniform and the blind hole rate is low.

2. Porcelain slurry has a neat cross-section after coiling, and the inner and outer tightness is consistent, which meets the relevant national standards; there is no obvious indentation of the thin strip after shearing.

Reticulated Cff can effectively remove all kinds of inclusions with a fineness of micron level in aluminum water, so that the aluminum water becomes a stable laminar flow, which is conducive to flushing.

It has a unique mullite-corundum structure, good mechanical strength and chemical stability, and excellent resistance to aluminum erosion.

Strictly controlled hole size and through-hole rate can obtain stable filtration effect.

There is a sealing ceramic fiber gasket around the foam ceramic filter plate, which helps the sealing of the filter disc in the filter box and ensures that there is no bypass of molten metal.

Sorry, the comment form is closed at this time.