26 8月 Sell Casting Filter

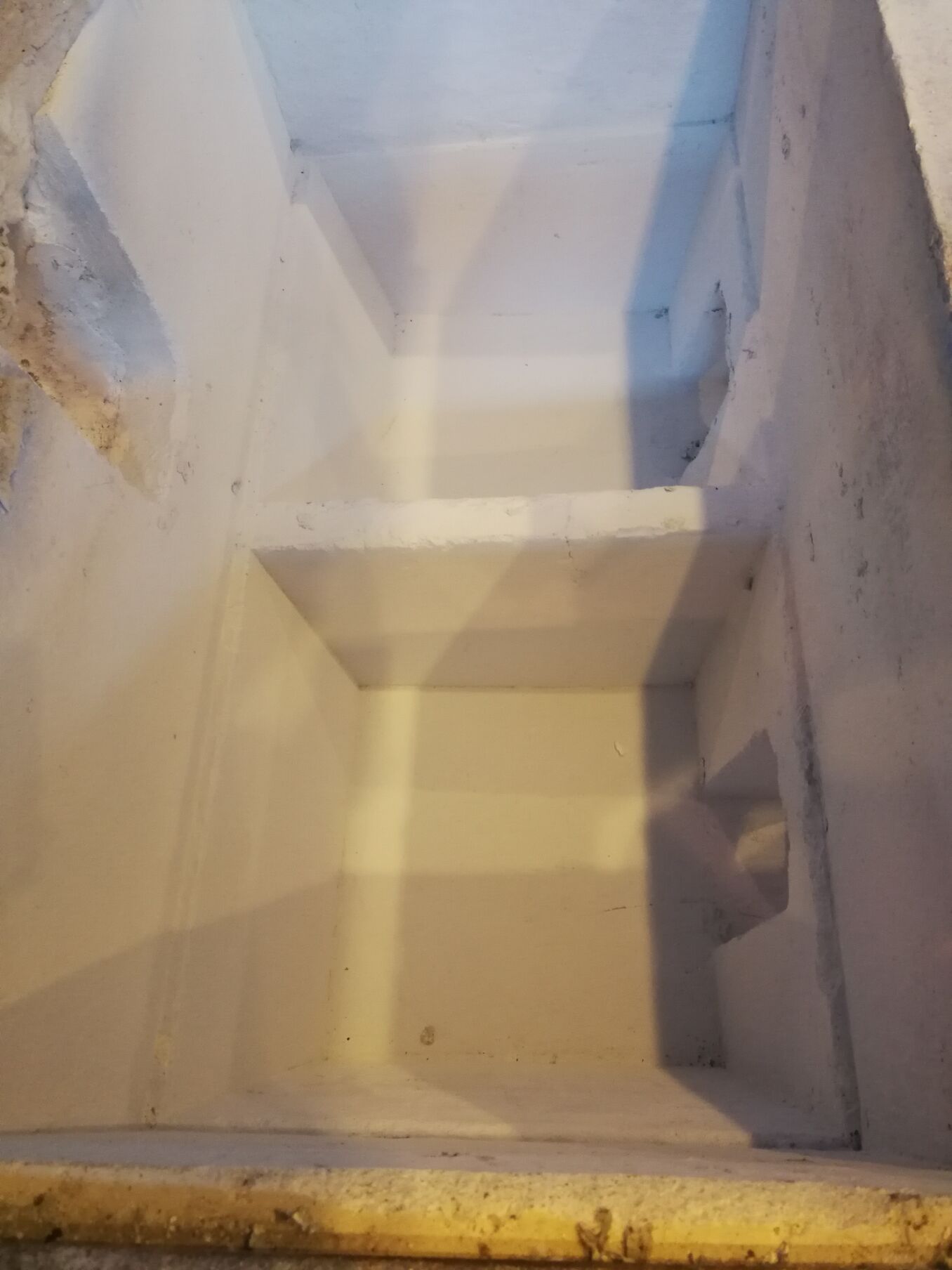

Sell Casting Filter to Rusal and get feedback on high quality products.

According to Rusal, it removes the inclusions between the refining system and the mold table. The ability of the ceramic foam filter to capture these inclusions is important to maintain a clean ingot during the metal hardening process. This ensures the quality and productivity of downstream operations such as forging, extrusion, and rolling.

Adtech has always been committed to ensuring that our customers have access to the best technology available on the market and are committed to producing the highest quality billets, castings or ingots. Our guarantee is not only for customers, but also for customers’ continuous development. Our technology provides casting quality for the most important end product applications. Sell Casting Filter: sales@adtechamm.com

Cast ceramic foam filters-these filters are only used for aluminum castings. Currently, the market’s leading suppliers offer various sizes and thicknesses. Need to choose the right things when necessary. If your requirements do not meet the general size, you can order custom sizes. In order to avoid re-oxidation of molten aluminum during the casting process, pressureless casting technology can be used. While improving the manufacturer’s production efficiency, it can also prepare Casting Filter for the next large shipments. Sell Casting Filter: sales@adtechamm.com

Casting aluminum is a process in which aluminum in a molten state of bai is injected into a mold, and an aluminum part of the desired zhi shape is made through a cooling shape du. The aluminum used for the dao of the cast aluminum is called cast aluminum alloy. Manufacturing principles of aluminum casting:

①When the aluminum ingot and the master alloy are melted, the aluminum is first added, and then the master alloy is added.

②When smelting with a precast ingot, first add the precast ingot, and then add the necessary amount of aluminum and intermediate alloy. When the furnace material is composed of prisoner furnace materials and aluminum ingots, the most part of the furnace materials is melted first.

④If the capacity of the furnace is enough to add multiple furnace materials at the same time, please add the ingredients with close melting point first.

⑤Furnace materials that are easy to burn out and have low melting points, such as magnesium or zinc, are put in last.

⑥ During continuous melting, a part of the molten aluminum must be retained in the crucible to accelerate the melting of the next furnace.

⑦When using flux, please add flux when the furnace material starts to melt.

Sorry, the comment form is closed at this time.