28 11月 Solution purification of aluminum alloy

Solution purification of aluminum alloy

With the development of science and technology and industrial production, especially the rapid development of aerospace, missile, aviation and electronic technology, the quality requirements of aluminum alloys are increasingly strict, most deformed aluminum alloy materials.

In addition to requiring acceptable chemical composition and mechanical properties, it also requires acceptable intrinsic quality and surface quality.

However, the conventional smelting process cannot fully meet these requirements because of the excessive gas and non-metallic inclusions.

In order to reduce the influence of gas and non-metallic inclusions, on the one hand, people put forward strict requirements on the raw materials and smelting process of alloy preparation, and on the other hand, they are committed to research and application of advanced new technologies for melt purification.

Purification becomes an extremely important production process for aluminum alloys. Advanced purification technology is very important to ensure the metallurgical quality of aluminum alloy and improve the final performance of the product.

Solution purification of aluminum alloy

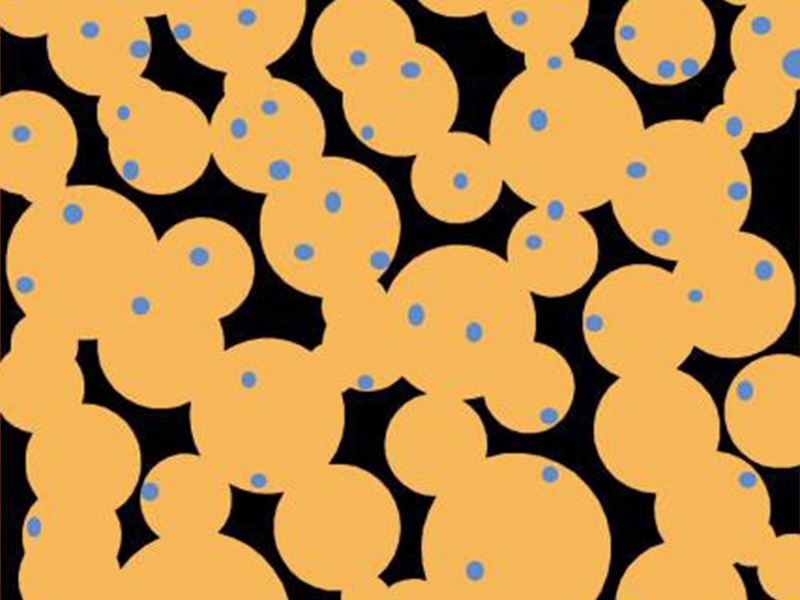

Aluminum alloy is easy to inhale and oxidize during the casting process. Therefore, gases and various non-metallic inclusions are present in the melt to different extents, causing defects such as looseness, porosity and inclusions in the ingot.

Significantly reduce the mechanical properties, processing properties, fatigue resistance, erosion resistance, anodizing properties of aluminum, and even lead to product scrap.

Solution purification of aluminum alloy

In addition, due to the influence of raw and auxiliary materials, there may be some other metals in the solution that are harmful to the solution.

For example, alkali and alkaline earth metals such as Na and Ca, some alkali metals have adverse effects on the performance of most aluminum alloys. For example, in addition to causing “sodium brittleness” in sodium-containing Al-Mg alloys, sodium also reduces the fluidity of the solution. It affects the casting properties of the alloy.

Therefore, special process measures are needed during the casting process to remove gases, non-metallic inclusions and other harmful metals in the aluminum alloy to ensure the quality of the aluminum alloy.

No Comments