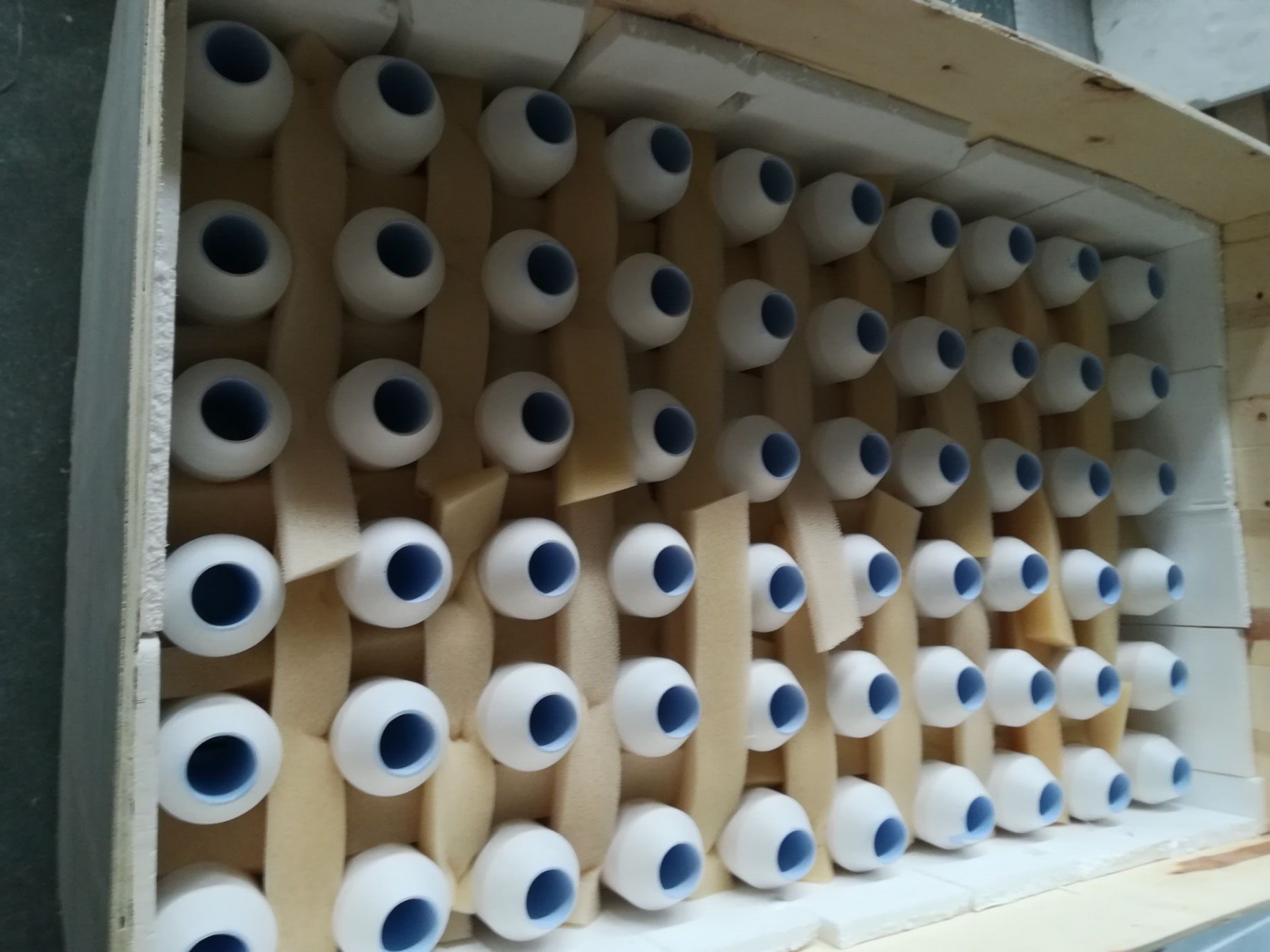

05 3月 Submerged Entry Nozzles

Submerged Entry Nozzles and the integral stopper rod open and close in the tundish to control the position of the stopper rod head to the water port of the tundish to adjust the flow of molten aluminum into the mold. It is an aluminum liquid flow control device used on aluminum continuous casting and rolling mill equipment.

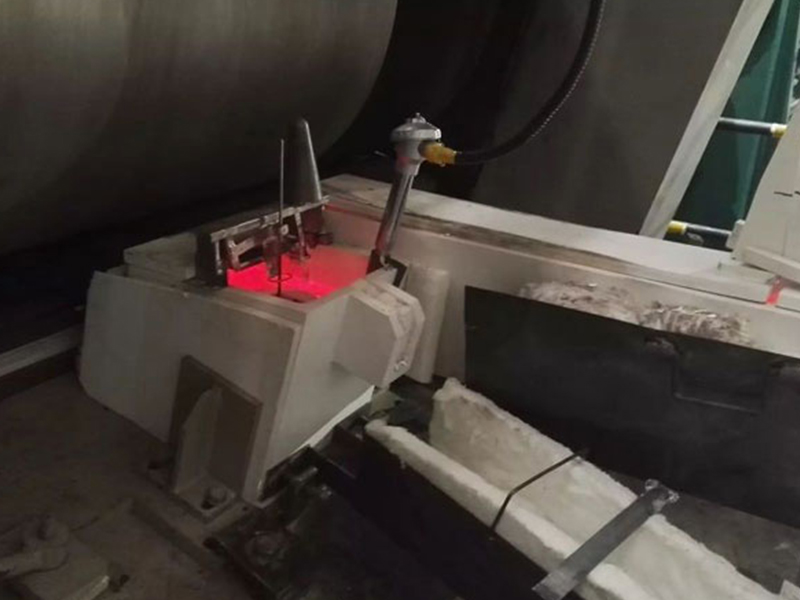

The flow control of the sizing nozzle is to control the flow of molten steel into the mold by changing the inner diameter of the nozzle. Both have their own advantages and disadvantages in terms of service life and pulling speed control.

In production, different flow control processes can be selected according to the characteristics of the aluminum alloy produced.

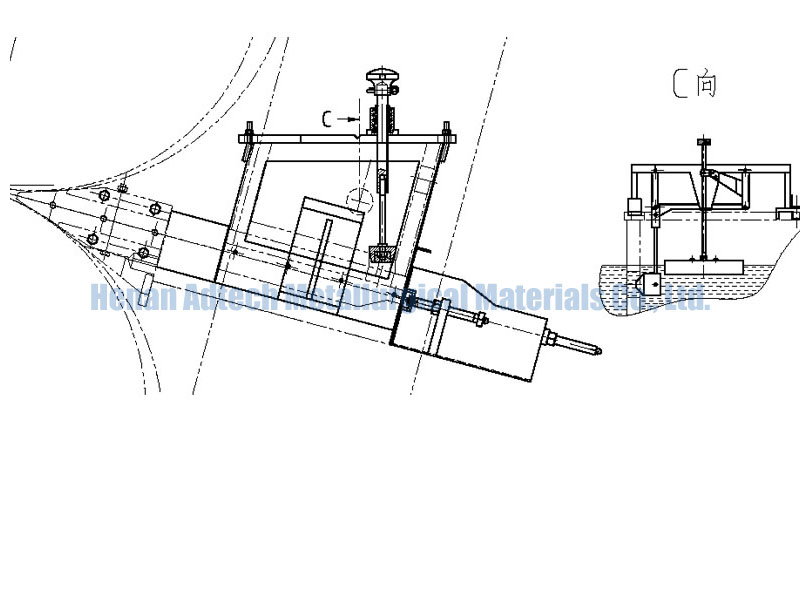

The aluminum liquid flow control device includes a flow control groove, a flow control baffle, and a flow control coupling. The flow control baffle is provided with a flow control port, and the flow control coupling is fixedly installed in the flow control flow groove. on.

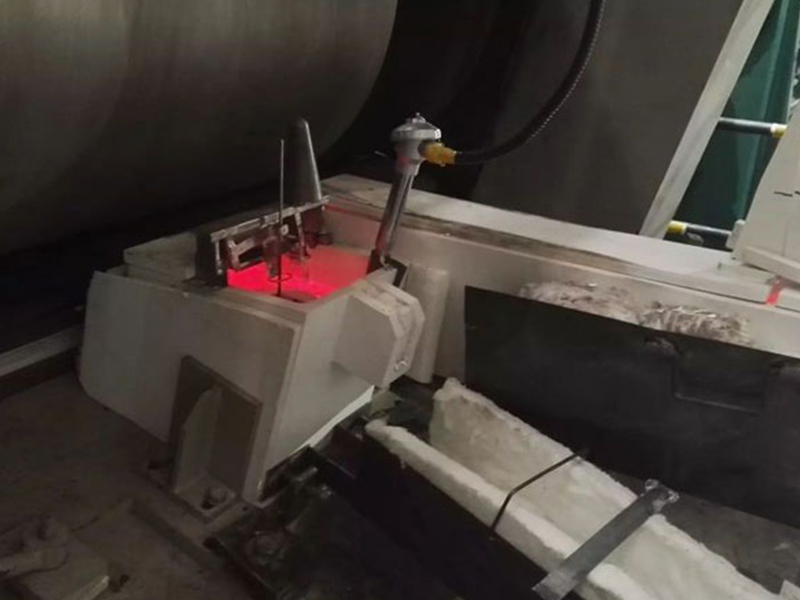

The liquid level of the front box of the casting and rolling mill is a very important process parameter to ensure the stability of the casting and rolling production process, and the key part to ensure the high stability of the liquid level of the front box is the aluminum liquid flow control device, which includes the Submerged Entry Nozzles.

Therefore, the stability of the liquid aluminum flow control device directly affects the product quality of the cast-rolled plate produced by the cast-rolling mill.

Submerged Entry Nozzles make the completed part of the molten aluminum flow control function in the equipment far away from the position of the front box device. The height change of the molten aluminum level in this embodiment reduces the impact on the height of the molten aluminum level in the front box device.

At the same time, in this embodiment, the height of the liquid aluminum level can be adjusted by adjusting the height of the float, which improves the accuracy of the liquid aluminum flow control device in the original equipment and ensures that the height of the liquid aluminum level is within the range of flow control accuracy.

No Comments