22 11月 The Components of The Hot Chamber Die Casting Machine

The Components of The Hot Chamber Die Casting Machine

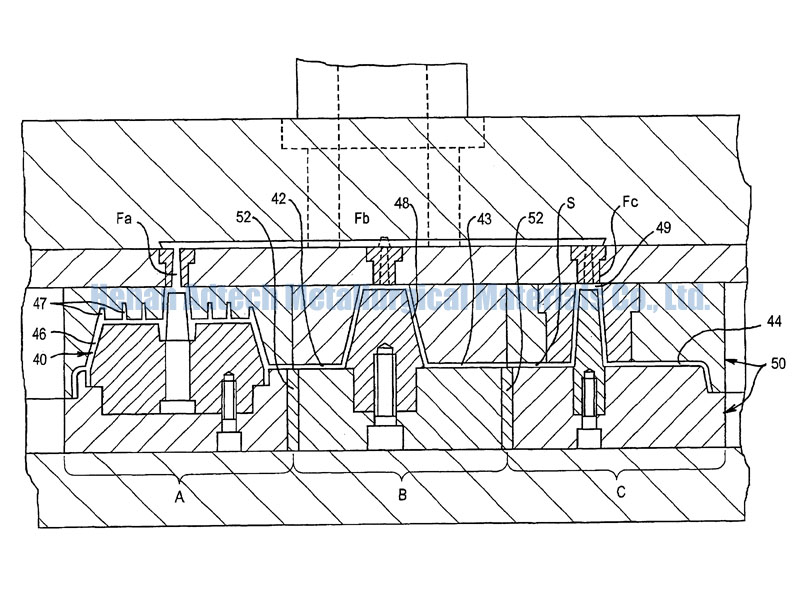

The injection mechanism of a hot chamber machine is immersed in the molten metal. The furnace is attached to the machine by a metal feed system called a gooseneck.

Hot Chamber 1

The die is closed and the piston rises, opening the port, allowing molten metal to fill the cylinder.

Hot Chamber 2

Next, the plunger seals the port, pushing the molten metal through the gooseneck and nozzle into the die cavity where it is held under pressure until it solidifies.

Hot Chamber 3

The die opens and the cores, if any, retract. The casting remains in only one die half – the ejector side. The plunger then returns, allowing residual molten metal to flow back through the nozzle and gooseneck.

Hot Chamber 4

Ejector pins push the casting out of the ejector die. As the plunger uncovers the filling hole, molten metal flows through the inlet to refill the gooseneck.

Hot Chamber 5

Visit our die cast process page to view a short video on the differences between the hot and cold chamber die casting processes.

Zinc & Magnesium Die Casting Company

Dynacast works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both cold chamber and hot chamber capabilities that include both conventional and multi-slide die casting. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team today to get the conversation started.

No Comments