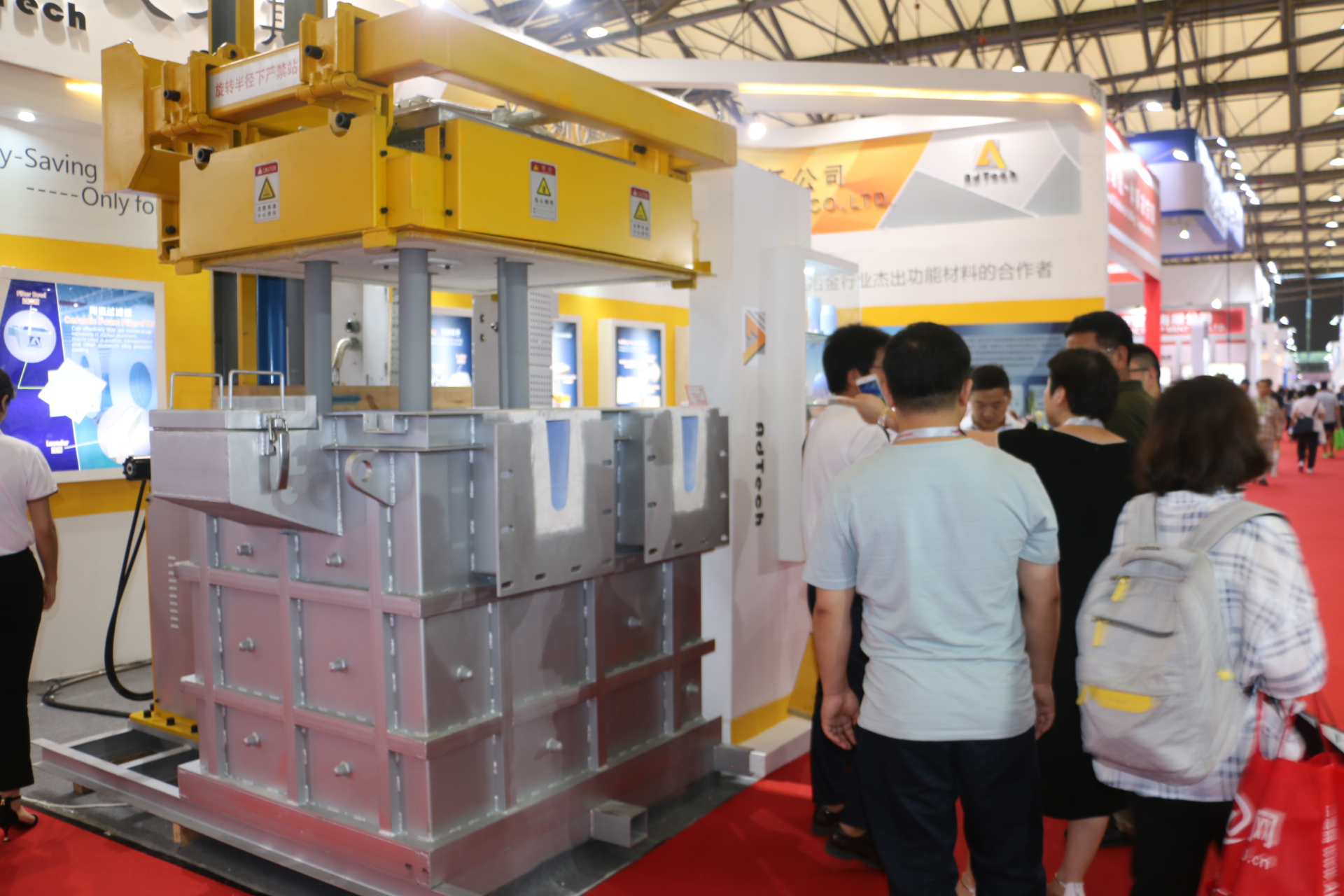

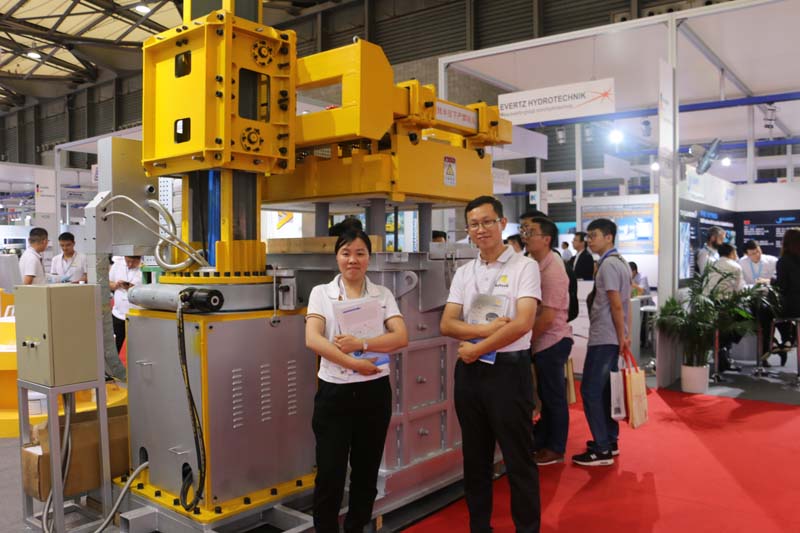

25 10月 Three rotor degassing box

Three rotor degassing box

Three rotor degassing box tank is specially designed for online degassing of flow tanks with large aluminum flow, high gas content and high inclusions.

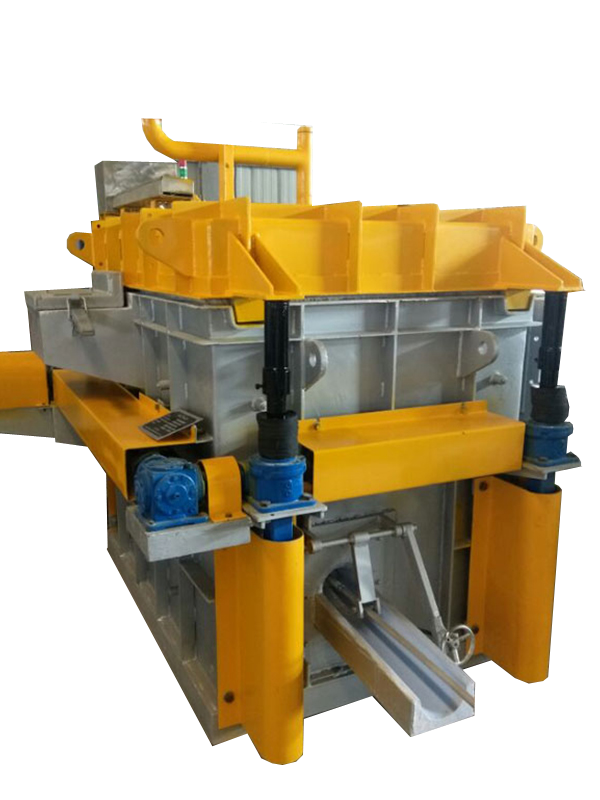

It has three agitating rotors that can independently control the rotational speed and gas flow, which can be more The aluminum fluid provides strong degassing refining capacity, the equipment is connected to the launder, the three rotors of the equipment can be lifted as a whole.

And can be turned at a certain angle to facilitate the replacement of graphite fittings, while the filter plate is used on the degassing tank.

The flow cell is divided into three independent degassing spaces corresponding to the three rotors, thereby forming a three-stage degassing.

And the filter plate makes the most downstream flow channel aluminum slag not excessive.

The corresponding degassing groove of each rotor They are equipped with independent slag slag for easy slag separation.

The well-insulated design of the equipment provides 24-hour online uninterrupted degassing.

Three rotor degassing box is equipped with a gas under-pressure alarm function. When the inert gas supply source pressure drops to a limited pressure, it can automatically alarm and prompt the operator to change the gas source through the warning light to avoid the occurrence of unqualified aluminum liquid due to lack of gas. The equipment has three rotors. When the equipment is used as an online degassing equipment, please prepare the spare air source in advance to facilitate timely replacement during undervoltage. (For the three rotors, the gas supply is large. It is recommended to establish a gas supply center to provide high purity. Nitrogen).

The three rotors can be independently controlled and continuously degassed layer by layer.

It can improve on-line degassing purification for large flow of aluminum liquid and improve the degassing efficiency of aluminum liquid.

When the set degassing time is completed, the rotor automatically stops.

The gas supply is automatically turned off, the indicator light flashes to alert the operator, and the safety is high.

When it is used as the online degassing, it can continuously operate continuously.

Using nitrogen or argon as the degassing medium, the advanced degassing principle greatly reduces the elimination.

Gas time, improve efficiency, reduce refining cost, no pollution to the environment, greatly improve the working environment. The inert gas flow is controllable, can be optimally set, can greatly reduce waste products caused by bubbles and inclusions, and greatly improve the finished product. Rate, improve the mechanical properties of castings.

Provides a stable and repeatable degassing effect, enabling efficient production for customers without affecting the production process.

Three rotor degassing box main shaft and the motor are equipped with air cooling devices, which can effectively reduce the operating temperature of the main shaft and the motor and prolong the service life.

The bottom of the equipment is equipped with an insulation layer with excellent thermal insulation performance, which can prevent the temperature of the aluminum liquid from being too high. Deformation.

Set with emergency shutdown button, easy and safe switch machine, solid structure, simple maintenance, low maintenance requirements.

The degassing principle of the three-rotor degassing box is stirring the aluminum liquid through the controlled rotating graphite shaft.

And the rotor, and simultaneously injecting the metered inert gas into the aluminum liquid through the rotor and breaking it into tiny bubbles to uniformly disperse it in the liquid.

In the molten metal, the gas partial pressure of the bubble is zero.

Since the partial pressure of hydrogen in the aluminum liquid is high, the hydrogen in the aluminum liquid continuously diffuses into the bubbles, and at the same time, some non-metallic inclusions in the aluminum liquid are adsorbed on the surface of the bubble

And inertness of useless hydrogen and some non-metallic inclusions adheres.The gas bubbles float up to the liquid surface. When there is a special degassing filter box, the impurities are isolated before the pouring, and then the degassing principle is recognized by removing the hydrogen and removing the oxide inclusions.

High efficiency and good effect, does not affect the production process, can improve the purity of aluminum liquid in a short period of time, reduce the scrap rate, improve production efficiency, improve the mechanical properties of castings, enhance the competitiveness of products, which is the traditional degassing method. Unable to reach.

No Comments