05 May Troughs and Launders

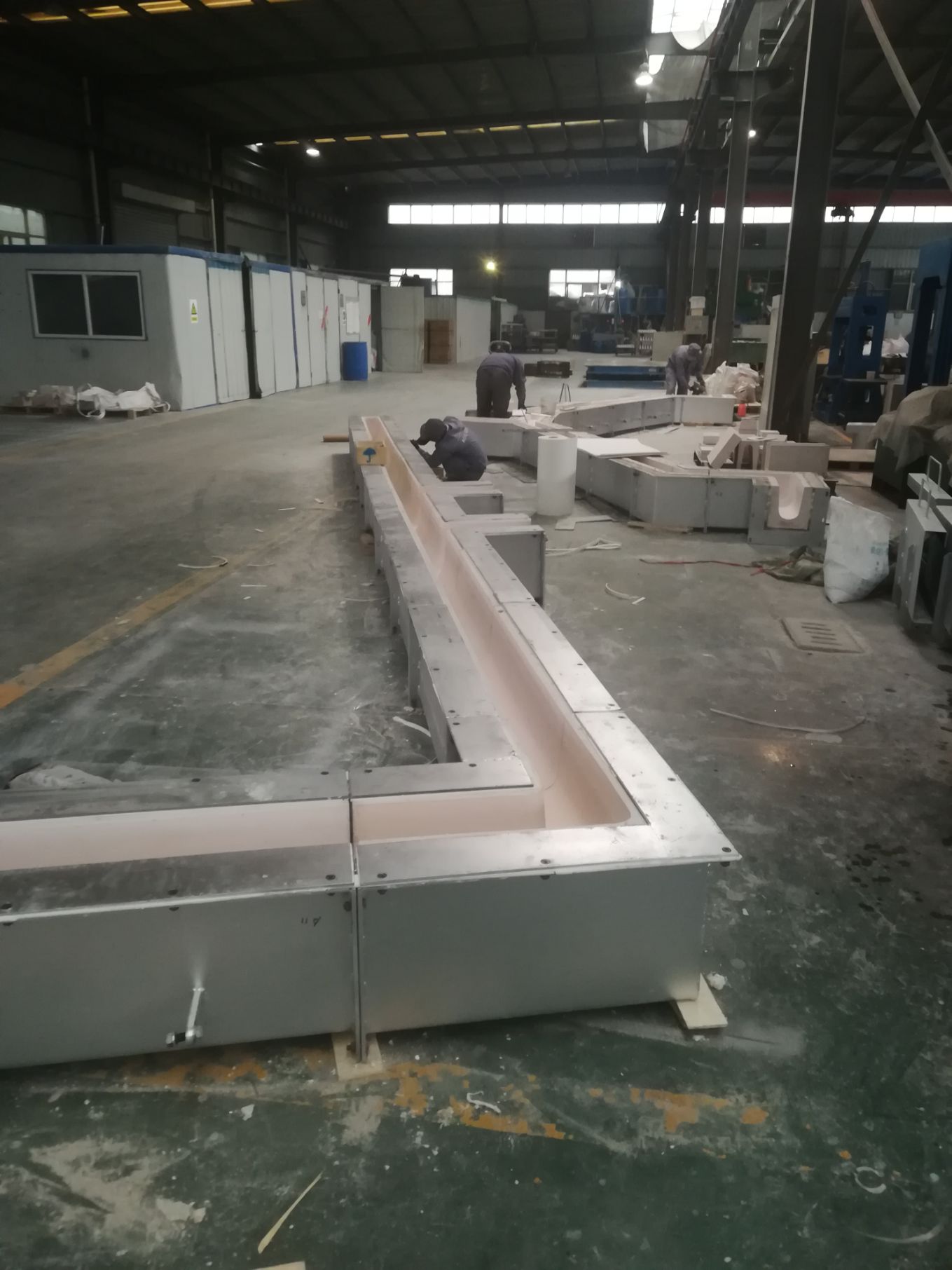

Troughs and Launders

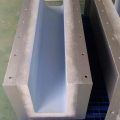

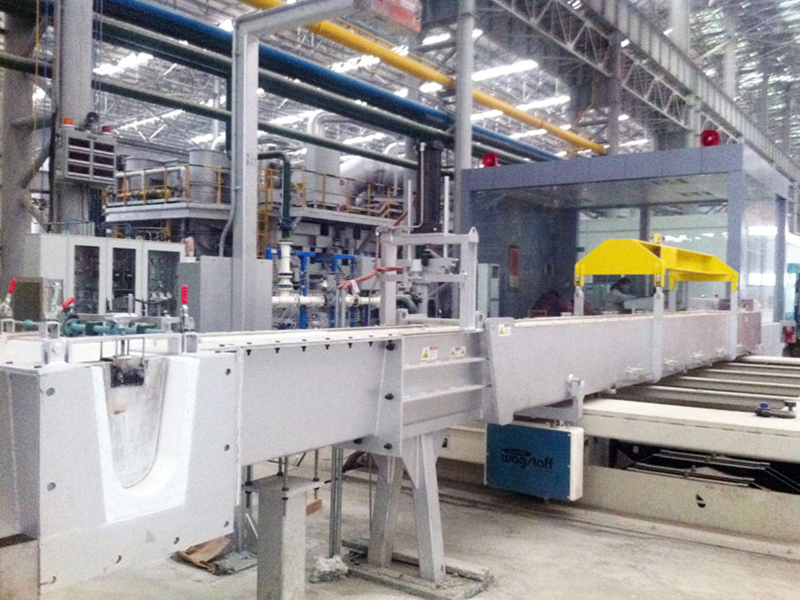

AdTech Troughs and Launders are installed between the furnace and the casting machine, withing 2 functions: conveying and insulation.

It is mainly used for aluminum liquid transportation between aluminum alloy melting furnace, purification furnace, casting platform, degassing outside the furnace and filtration.

Troughs and Launders advantages

1. Good insulation performance, reasonable design and long service life;

2. It is integrally molded with noble molten material and has high dimensional accuracy;

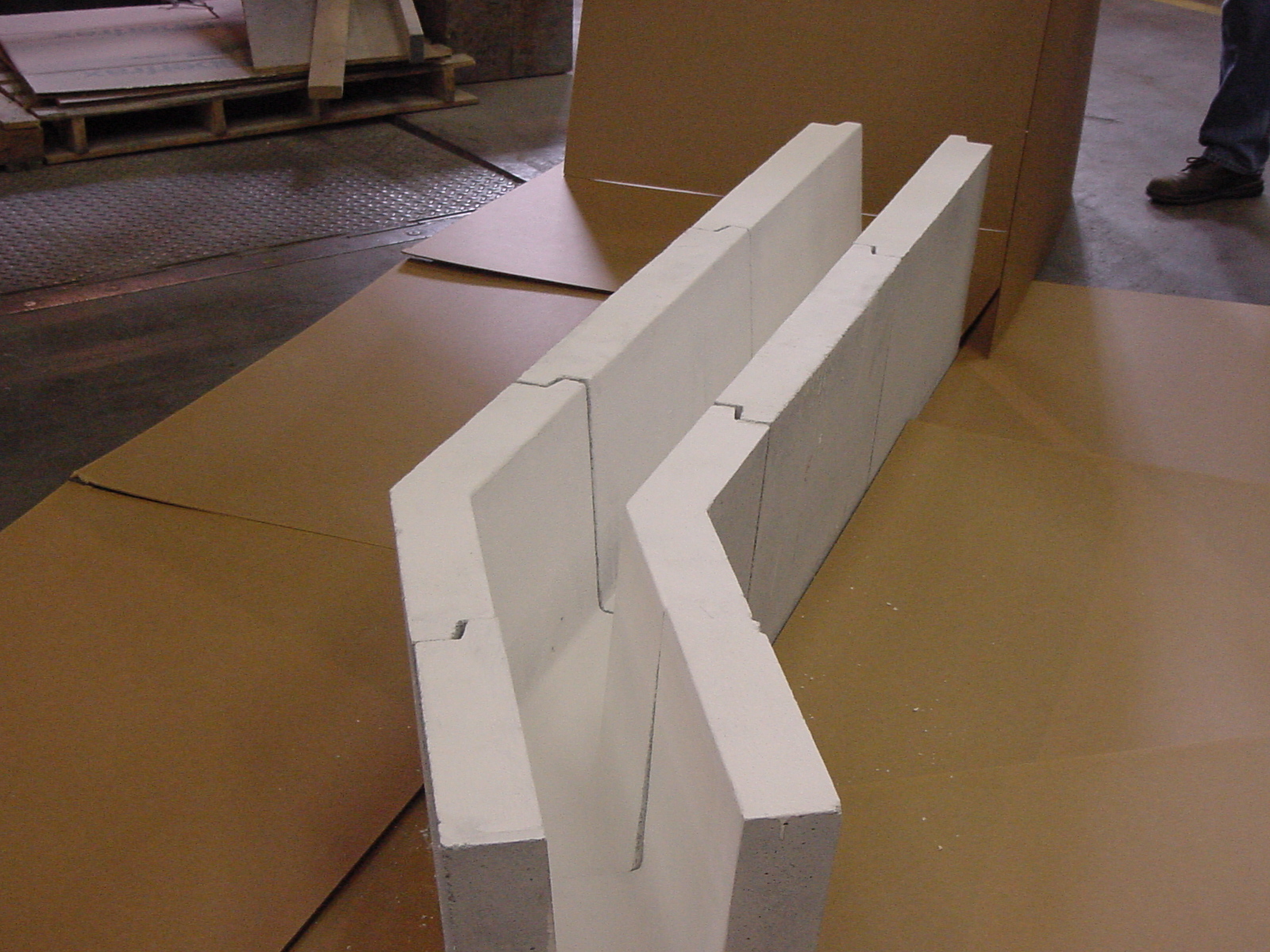

3, the inner lining strength, erosion resistance, heat shock, smooth surface;

4. The inner liner has strong corrosion resistance to aluminum, zinc and magnesium alloys, enhances the use effect of molten metal transfer equipment, and strengthens the service life of special alloys;

5, the temperature drop of the metal liquid during use is 2 ° C per meter, resistant to erosion, heat shock, smooth surface.

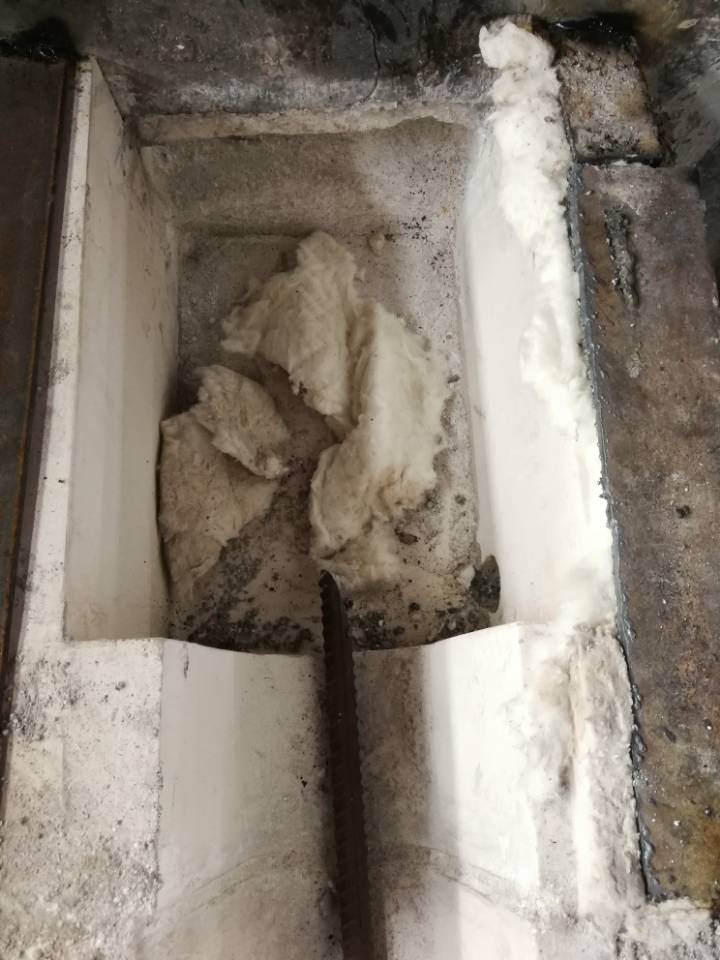

Corresponding to the drawing structure, the flow cell is installed to ensure that the overall flow path is clean, no damage, no gap.

Uniformly preheat the installed flow path, heat up at a constant speed for 6-8 hours, check the surface of the lining red, ie 800 °C, to remove the adsorbed crystal water, close to the casting temperature, safe and efficient use.

Troughs and Launders Features

The texture is tough and strong against wind erosion.

Seamless lining.

Low heat storage and low heat loss.

Direct contact with the flame for hot surfaces.

Excellent construction and installation performance.

Excellent thermal shock resistance.

High compressive strength and long service life.

The sound absorption effect is remarkable.

Sorry, the comment form is closed at this time.