05 3月 Tundish Upper Nozzles

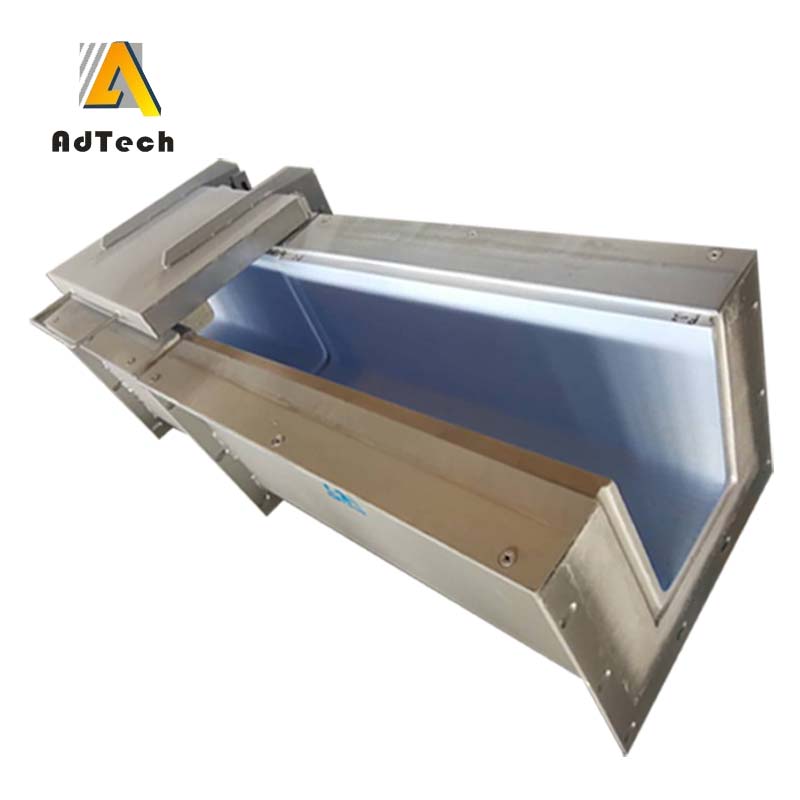

Tundish Upper Nozzles uses aluminum fusion-casting flow control system, which has good thermal insulation performance, high temperature resistance, non-stick aluminum, high strength, no delamination, and long service life.

Applicable to aluminum casting industry: the key components needed in the production process of aluminum rods, large slabs and aluminum rods. The launder system, filter system, degassing system, casting table, transfer pipe, control rod, transfer plate, runner gate and other special-shaped parts of aluminum liquid.

Adtech manufactures refractory and casting materials required by the aluminum smelting and casting industry. It has a complete range of products and can produce products of various specifications. product category:

1. Aluminum casting general refractory material: aluminum silicate plug. plug; asbestos plug: silicon blanket; aluminum silicate fiber paper.

2.Matching series of refractory materials for aluminum rod casting: shunt plate; adapter plate; casing; float: plug.

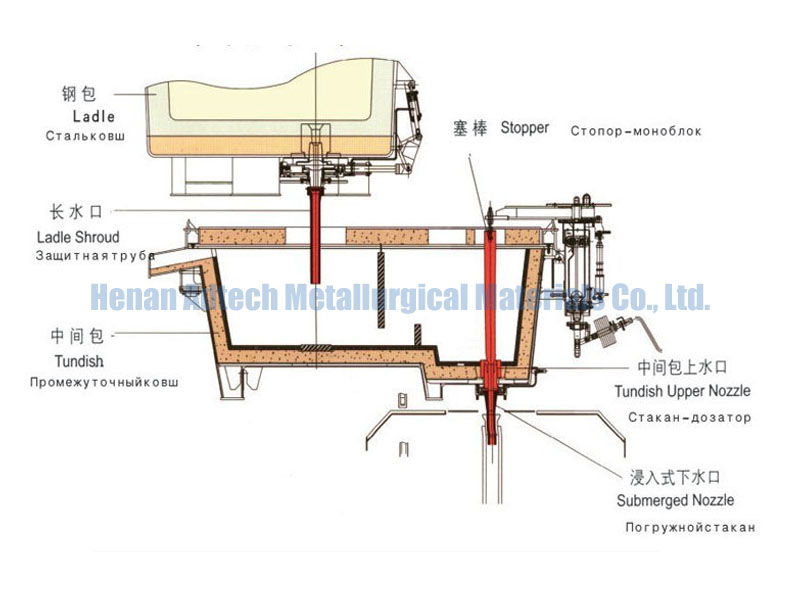

3.Supporting series of refractory materials for aluminum plate casting and rolling: Stopper, Tundish Upper Nozzles.

4.Matching series of refractory materials for aluminum wheel casting: sprue cup; sprue sleeve.

5.Supporting series of refractory materials for aluminum water filtration: filter cloth (aluminum water filter net); foam ceramic filter plate: filter box.

6.Graphite products; graphite ring, graphite rotor, graphite plug, graphite baffle.

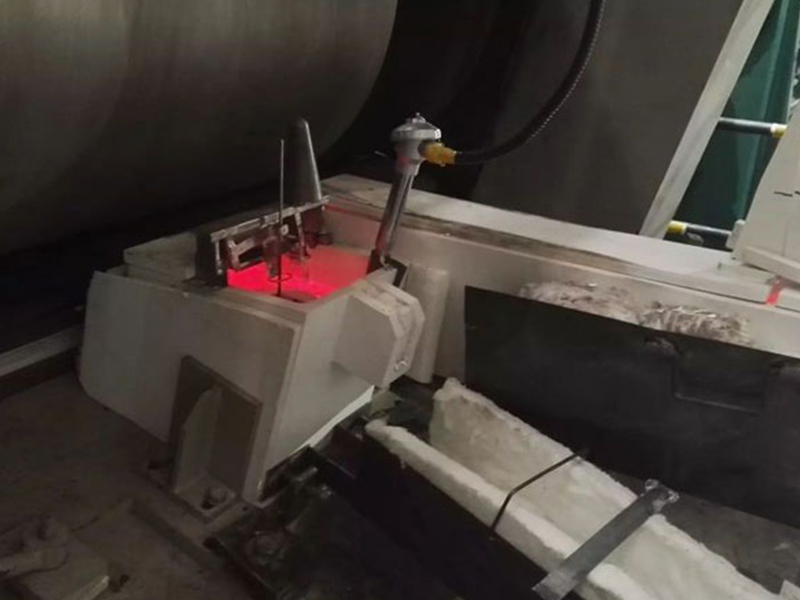

The liquid level of the front box of the casting-rolling mill is a very important process parameter to ensure the stability of the casting and rolling production process, and the key part to ensure the high stability of the liquid level of the front box is the aluminum liquid flow control device, which includes the Tundish Upper Nozzles.

Therefore, the stability of the liquid aluminum flow control device directly affects the product quality of the cast-rolled plate produced by the cast-rolling mill.

No Comments