06 11月 Types of Ceramic Foam Filters Used In Casting

Types of Ceramic Foam Filters Used In Casting

To be used in the release of heat at various levels during casting, the ceramic foundry filter needs to be stronger. The best quality materials are used in filter manufacturing. The filters are classified according to their strength, accuracy, and tensile strength. For casting various kinds of materials different types and sizes of filters are used.

Three Major Foundry Filter Varieties:

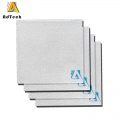

Adtech Ceramic Foam Filters – These filters are solely used in aluminum casting. Currently, diverse sizes and thicknesses are being offered by market-leading suppliers. You have to choose the right one as per your requirements. You can order a customized size if your requirement does not fit the common sizes. To avoid re-oxidation of the molten aluminum during casting, you can go for a pressure-free casting technique. It boosts the productivity of the manufacturer while keeping the filter ready for the next big consignments.

Types of Ceramic Foam Filters Used In Casting

Cerazirk Filters – Mostly it is used only for iron, steel, and stainless steel casting. The most advanced ZrO2 filters changed the market scenario. For Cobalt- and Nickel-based alloy casting, this mechanism works great. Mainly it is a great performer in low-carbon as well as ultra-low-carbon steel casting.

Ceramic Filters – It is the most used and versatile option for casting aluminum, brass, bronze, copper, iron, and steel

. Mostly it is used in iron and non-ferrous casting units. You just need to find the accurate thickness of the filter to amplify the bending strength for higher productivity.

The use of vacuum degassing or AOD converter-like techniques capably increases the filter capacity. For a higher performance and better durability, the right choice of filter matters.

No Comments