21 5月 United Company Rusal Plc Supplier-Aluminum Filter Box

United Company Rusal Plc Supplier-Aluminum Filter Box

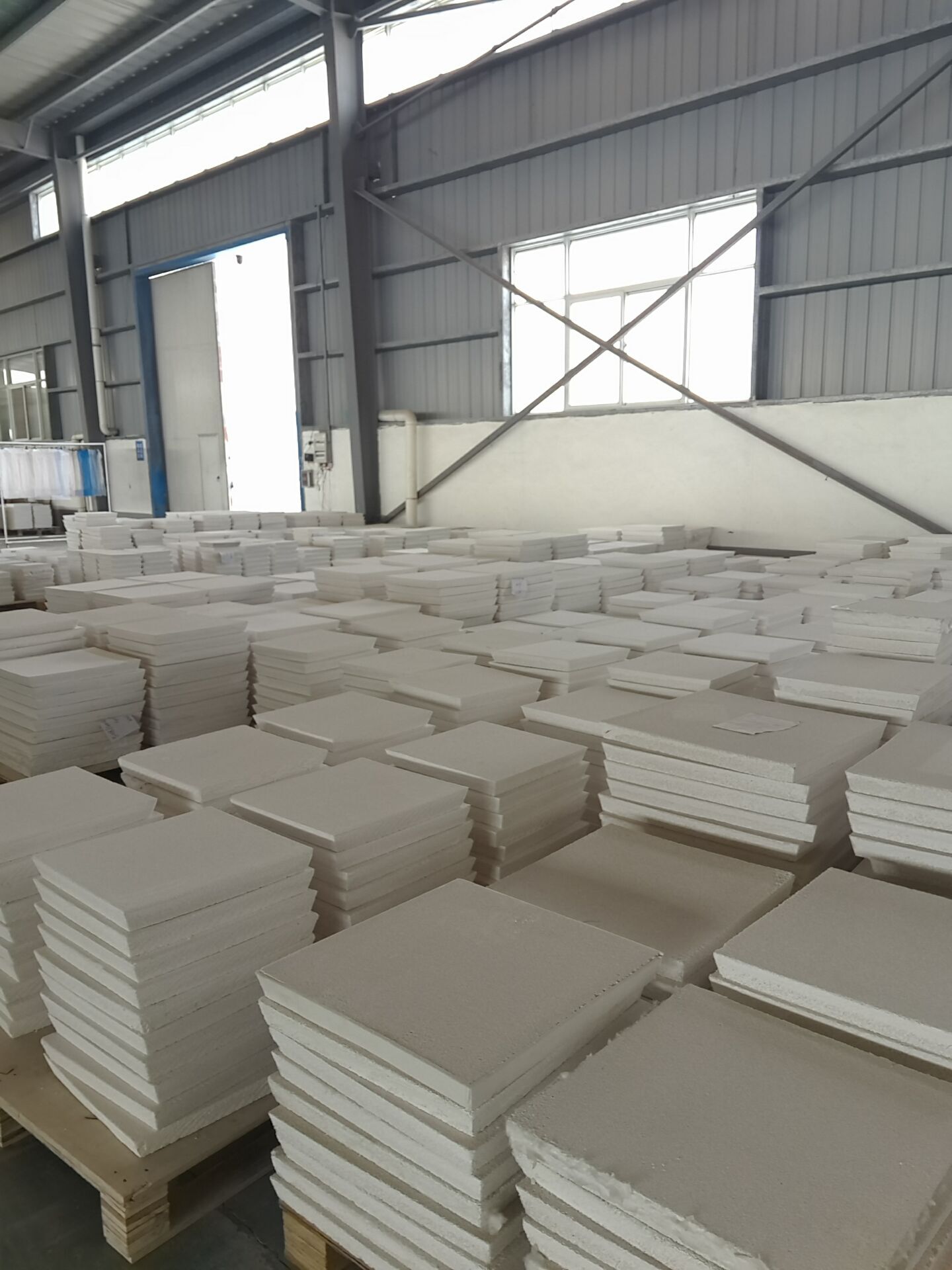

Aluminium industrial filter box Designed for use in the aluminum industry as a working lining for aluminum water

transfer equipment, such as aluminum flow troughs, filter boxes, etc., in direct contact with aluminum water.

Can also be used as aluminum water holding furnace, lining and aluminum water bag, lining material.

The aluminum industrial filter box uses fused quartz as the main raw material and utilizes the excellent volume stability of the fused quartz material.

In addition, the aluminum industrial filter box incorporates anti-stick aluminum additives that can prevent the penetration of aluminum water, making the whole material have excellent resistance.

Aluminium Adhesion The special design of the aluminium industrial filter box makes the casting surface smoother.

At the same time, cast fireproof lighter chute and degassing box castable have certain strength and good heat preservation performance.

For customers who use cast fireproofing, we provide free technical guidance and related technical documents.

United Company Rusal Plc Supplier-Adtech to Rusal Aluminum

The aluminum industrial filter box is a prefabricated product made of special materials.

It is an essential configuration for forming a stable filter cavity when using a ceramic foam filter plate to filter aluminum and aluminum alloy solutions.

The aluminum industry filter box and other products provided by AdTech Metallurgical Materials Co.,Ltd. have excellent heat resistance, high resistance to aluminum and the rate of erosion of the solution, good insulation properties, high strength, strong resistance to mechanical attack, molding size standards, Effectively realizes the filtration performance of ceramic foam filter plates and provides reliable support. In addition to the general specifications, it can be designed and manufactured according to the needs of customers.

United Company Rusal Plc Supplier-Adtech

This series of products is a necessary equipment for continuous filtering and semi-continuous casting filtration and purification systems to form a smooth filter.

United Company Rusal Plc Supplier-Adtech

Physical and chemical properties:

Wear resistance, high strength after burn, wear resistance, erosion resistance, non-stick slag, dense penetration resistance, non-stick aluminum, non-stick slag

Color: White Raw material composition: AL2O3≥70%

Physical properties

Density: 2.6g/cm3 Thermal conductivity: 700°C≤0.5W/M.K Maximum operating temperature: 1650°C Continuous use

temperature: 1200°C

Change after firing: 850°C*24h≤0.3% Compressive strength after burning: 850°C*3h≤60MPA

Technical data

Chemical composition: (main ingredient)

Silica – 63.5% Material Density — 1.905g|cm?

Alumina — 32% — 1.608g/cm?

Calcium Oxide – 3% Particle Size – – – – no more than 3 mm

Microsilica – 1%

Chemical composition does not include patented ingredients Maximum operating temperature – 1200 degrees

Bulk density g|cm

Heating to 230F (110°C) 2.11

932F (500°C) 2.05

1000F (540°C) 2.05

1750F (955°C) 2.02

Atmospheric compressive strength MPA

Heating to 230F (110°C) 66

932F(500°C) 43

1000F (540°C) 33

1750F (955°C) 17

Thermal conductivity W|MK

Heated to 300F (150°C) 1.21

600F (316°C) 1.11

800F(540°C) 1.08

No Comments