05 3月 Upper Nozzles for a Tundish

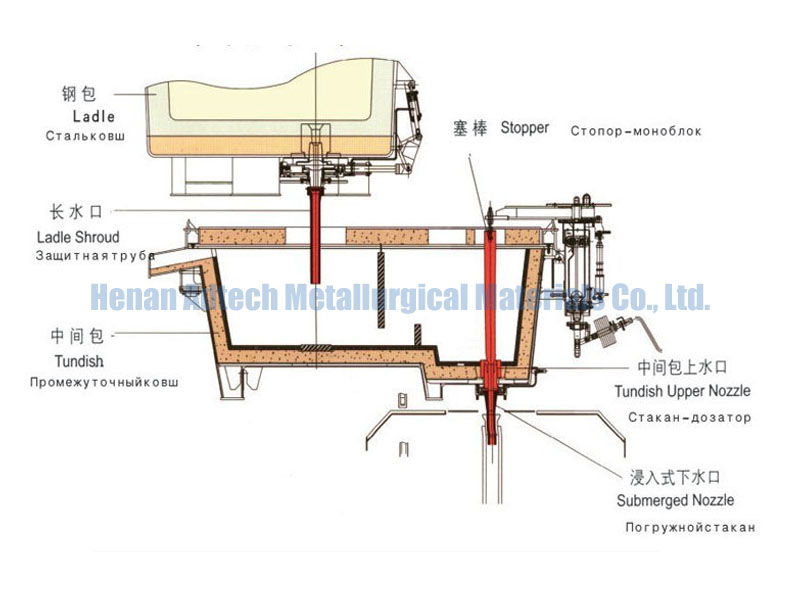

Upper Nozzles for a Tundish is an important part used in the aluminum and aluminum alloy casting process, mainly used in the field of aluminum liquid diversion in aluminum alloy casting.

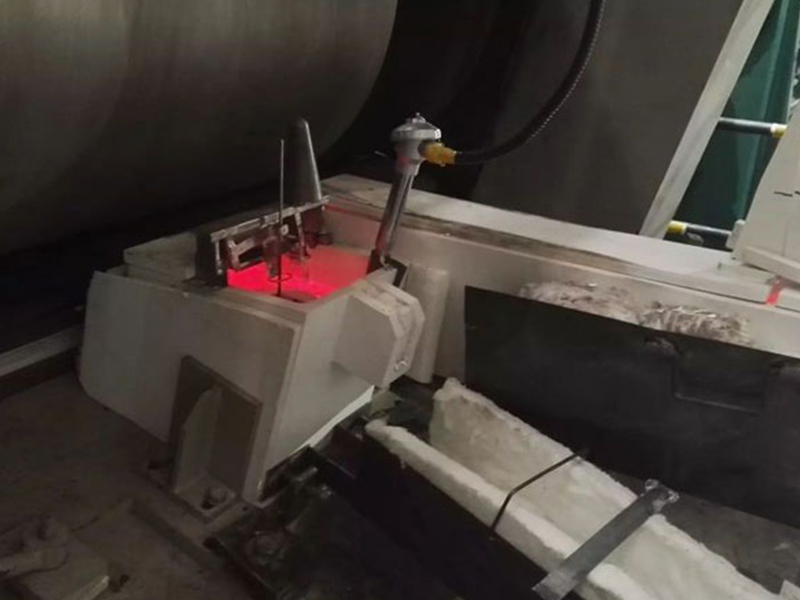

The aluminum melt flows through the high-level Alumina Tube to the insulation pipe, and then smoothly diverges to the low-level flow trough, the splitter plate or the transfer duct. Its main function is to solve the height difference problem in the casting process.

If the insulation flow pipe does not have a good drainage and insulation effect, the aluminum melt will not flow smoothly and safely to the casting platform, so that the aluminum liquid casting with different liquid levels cannot be completed.

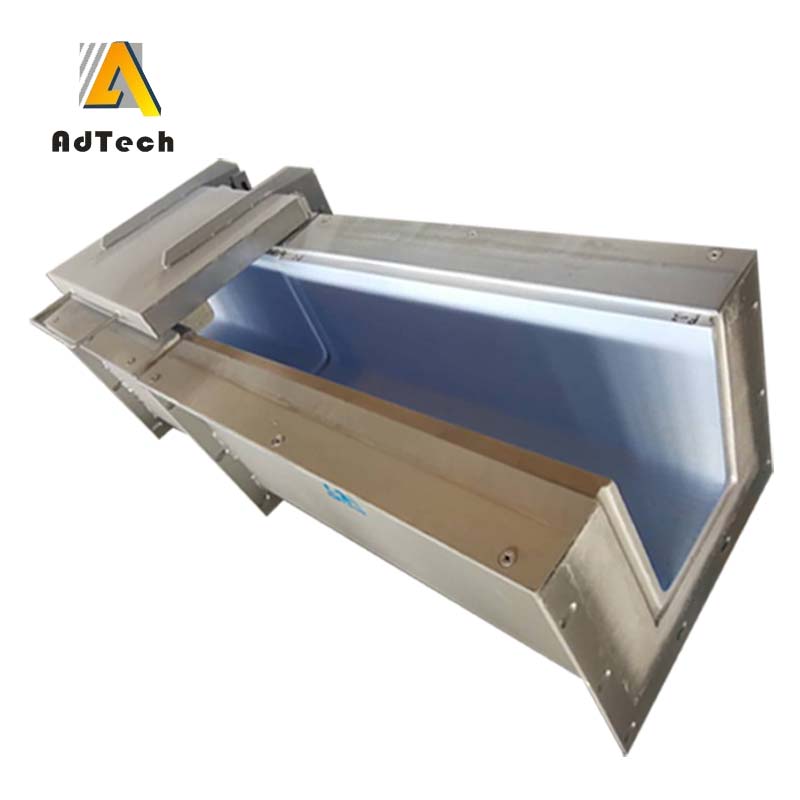

Upper Nozzles for a Tundish and the materials used are mostly castable or clay.

Insulation pipe made of castable material is heavy, requires high installation accuracy, poor insulation performance, and high cost.

Clay insulation pipes are evacuated, low in strength, easy to drop slag, and easy to bring slag during use, all of which need to be further improved and designed.

Insulation flow tube, the top of the insulation flow tube is outwardly horn-shaped, and the inside adopts a large upper and lower cone structure, which can play a role in smooth drainage, reduce turbulence of molten aluminum, and simple installation and splicing. The material is made of ceramic fiber to keep heat insulation. The flow tube has good thermal shock resistance and heat preservation.

In the existing aluminum alloy casting process, the aluminum liquid guide tube is mostly straight, and the aluminum liquid guide tube is mostly made of aluminum silicate ceramics, which has poor corrosion resistance, short service life, low density of molten aluminum, and The presence of filter residue and impurities affects the quality of cast products.

No Comments