29 3月 Refining Agent Usage

Refining Agent Usage

Many people don’t know much about the refining agent, but many people are still on the network to ask many questions about the refining agent, such as: the role of refining agents, refining agent formulations, refined oil composition, refining agent prices, refining agents Wholesale, manufacturers and suppliers. Let’s let Xiaobian introduce the above questions to everyone!

The refining agent is white (slightly grayish) powdery fine particles, the main components of which are chlorine salt and fluoride salt, and other compounds. After appropriate heat treatment and sieving, the particle size is uniform, which is beneficial to the refining tank in the carrier gas (N 2 Or under the action of Ar ) into the lower layer of molten aluminum uniformly, through the physical and chemical changes in the molten aluminum to form numerous small bubbles and aluminum liquid full contact, separation of aluminum in liquid [H] and other harmful gases; while refining agent contains Some substances can strongly adsorb and melt the oxides and suspended substances in the melt and adhere to the bubbles together.

As the bubbles rise, they are brought to the surface of the aluminum liquid, thereby achieving the purpose of refining and purifying degassing and slag removal;

It is economical and meets the production of high value-added, high-tech performance aviation, transportation and other aluminum alloy precision casting.

Such as: computer hard drives, micro-aluminum foil wool, printing PS base, can making materials, jet turbine engine fan leaves and other products.

Standard refining flux type

| Type | Function | Scope of Application | Dosage per ton | Refining temperature |

| 3RF | Degassing & Deslagging | Molten casting aluminum and alloy degassing, deslagging & purifying | 1.5-2.5kg | 700- 740℃ |

| 6RF | Degassing & Deslagging, better than 3RF | Refining of cable rod and alloy rod precise casting | s1.0-1.5kg | 700- 740℃ |

| 9RF | Environmental, without C2Cl6 | Refining of high purity & high magnesium molten alloy in furnace | 1.5-2.0kg | 700- 740℃ |

| 420RF | Degassing type | Refining and purifying of high precise aluminum, such as A356.2 and hub | 1 .5-2. 5kg | 710 – 730℃ |

| 560RF | Na free type, Degassing & Deslagging | Refining and purifying of 5 series aluminum alloy and hub in furnace | 1. 5-2.0kg | 720 – 740℃ |

| 33SF | Degassing & Deslagging | Refining and purifying of double Zero foil preform body in furnace | 1. 5-2.0kg | 720 – 740℃ |

| 66SF | Degassing & Deslagging | Refining and purifying of aluminum alloy precise casting in furnace | 1. 5-2.0kg | 720 – 740℃ |

| 120SF | Denatrium & Decalcium type | Removing micro scale of Na、Ca、H、Li in molten aluminum & alloy in furnace, refining and purifying efficiency | 1. 5-4.0kg | 735 – 745℃ |

| 220SF | Demagnesium | Removing micro scale of Mg in molten aluminum and alloy in furnace, refining and purifying efficiency | Can remove 1kg Mg with 5kg 220SF | 735 – 745℃ |

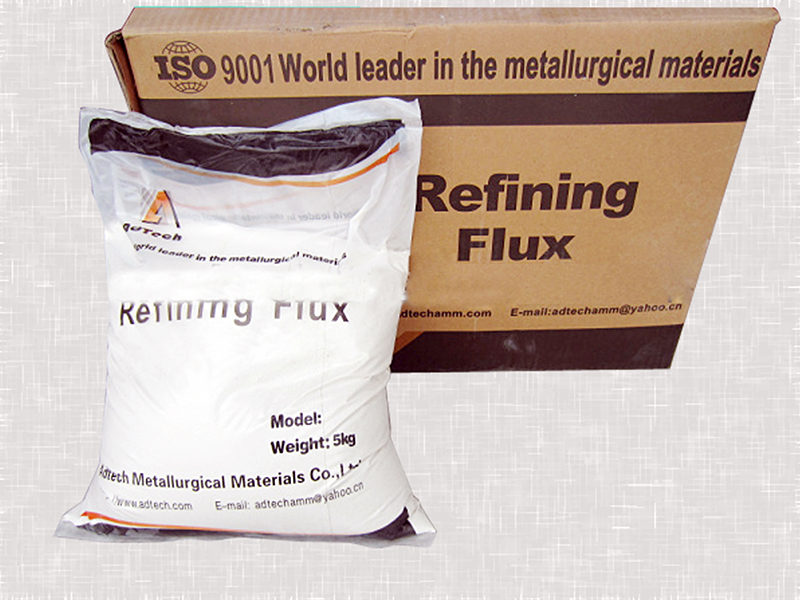

Packing Specifications:

| Item | Internal Packagin | Carton Packaging | Pallet Packaging | Special Packaging | Storage & Guarantee |

| Index | 2-5kg/bag | 25kg/carton | 1T/pallet | As per requirement | Stored in ventilated and dry environment,6 to 12 months |

No Comments