10 7月 Zirconia Foam Filter

Zirconia Foam Filter

Zirconia Foam Filter is made of zirconia ZrO2. Its heat-resistant temperature is higher than about 1760 ° C, with very high strength and excellent high temperature impact.

Aluminium Casting requires aspects of high strength and elongation requirements. Therefore Aluminium is very sensitive to defects caused by impurities.

Zirconia Foam Filter’s excellent properties can effectively remove impurities that ultimately lead to product quality defects. The impurities are mainly composed of non-metallic particles, slag, and refractory fragments, which improve the surface quality and mechanical properties of castings and reduce the scrap rate.

Foam Filter can make the aluminum liquid more evenly fill the cavity, and the molten metal has a higher turbulence tendency during casting. The turbulent flow through the three-dimensional pore structure of the ceramic foam filter is finally converted into a very stable laminar flow.

The laminar flow fills the cavity better, which reduces the impact corrosion of the metal solution on the casting cavity and significantly reduces the reject rate.

Non-metallic inclusions in castings are the most important cause of casting defects, which affect the surface finish, mechanical and processing properties of the casting and result in increased reject rates.

The Zirconia Foam Filter product is designed to remove the inclusions and reduce turbulence to achieve a fast and stable flow rate of molten metal, thus improving the quality of the casting.

It has a remarkable filtration effect on all aluminum and aluminum alloys. It is made of pure zirconia and has a temperature of up to 1760 °C, which is not sensitive to different casting temperature changes.

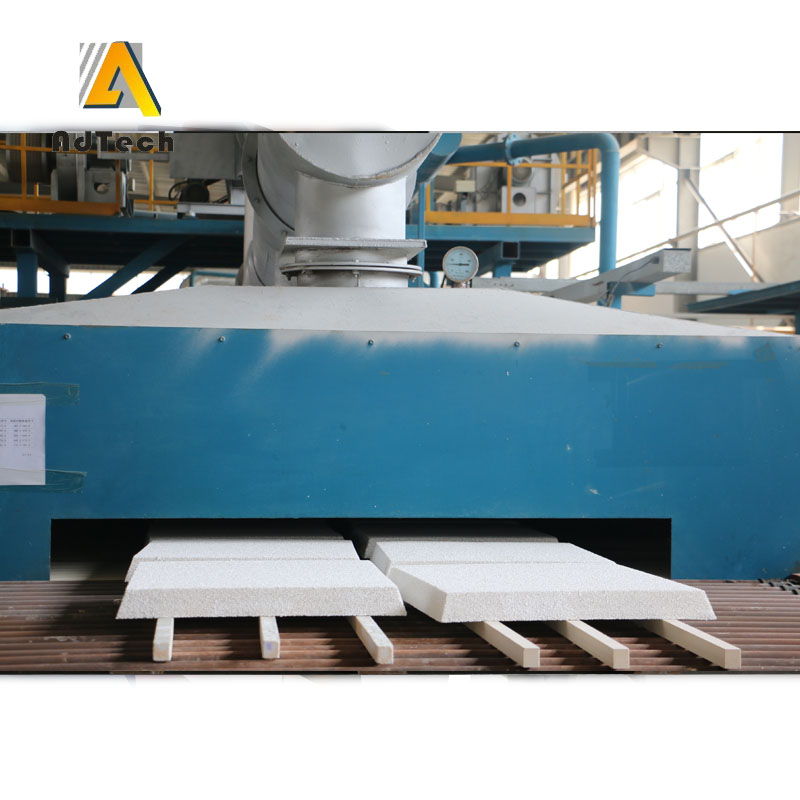

Excellent raw materials and advanced production technology ensure that Foam Filter has stable dimensional tolerances, meets the requirements of manual molding and more efficient mechanized production lines, and ensures that the quality of foundry products meets international quality standards.

Alumina foam ceramic filter for temperature 1250 ° C, suitable for filtration and purification of aluminum and alloy solutions.

In order to meet the ever-increasing quality of aluminum castings, the use of ceramic foam filters is becoming more and more important.

Foam Filter is also widely used in ordinary sand casting such as tidal casting and casting of permanent molds such as automotive aluminum parts casting.

How to use Zirconia Foam Filter

1. Clean the filter box.

2. Gently put the filter plate into the filter box and press the sealing gasket around the filter plate by hand to prevent the aluminum liquid from flowing.

3. Evenly preheat the filter box and filter plate to bring it close to the temperature of the aluminum liquid. Preheat to remove moisture and facilitate initial transient filtration. Preheating can be carried out using electrical or gas heating. Under normal circumstances, it takes about 15-30 minutes.

4. Pay attention to the change of the aluminum hydraulic head during casting. The normal starting head is 100-150 mm. When the aluminum liquid begins to pass, the pressure head will drop below 75-100 mm, and then the pressure head will slowly increase.

5. During the normal filtration process, avoid knocking and vibrating the filter plate. At the same time, the launder should be filled with aluminum water to avoid too much disturbance of the aluminum water.

6. After the filtration is finished, remove the filter plate in time and clean the filter box.

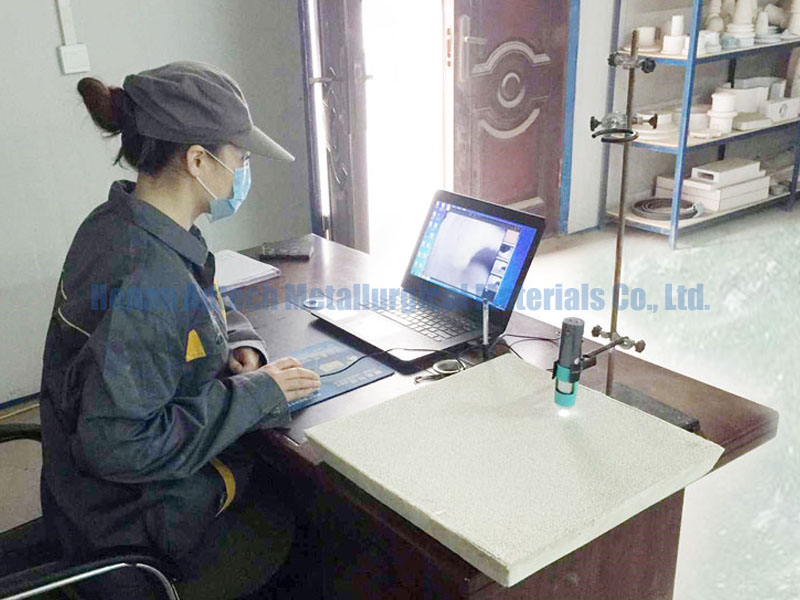

Zirconia Foam Filter transmittance

Transmittance refers to the effective filtration area of the foam ceramic filter plate product. The higher the light transmittance, the less blind holes are, and the more effective the filter holes (potholes), the better the filtering effect.

The foam ceramic filter plate to be inspected is placed on a light box with a built-in 200W incandescent bulb, and the square transparent plastic plate with a uniform 5.0×5.0 mm square is used to measure the area of the large surface of the filter plate, so as to calculate the test. The light transmittance of the filter plate is used to determine the light transmittance of the filter plate. In this standard, the transmittance (through-hole ratio) of the filter plate is specified to be 95% or more.

Zirconia Foam Filter compressive strength

In the process of transportation and use of the filter plate, the filter plate must withstand the impact of a certain pressure from the outside, so the index of compressive strength is also introduced in the standard as one of the basis for measuring the quality of the filter plate. The higher the compressive strength, the more durable the product, the better the quality, and vice versa.

In this standard, the index of compressive strength is determined to be 0.5 MPa or more.

Sorry, the comment form is closed at this time.